The Data Economy will revolutionise the Manufacturing Industry, but this (r)evolution risks to sharpen the gap between large enterprises and SMEs.

Data Economy will revolutionise Manufacturing Industry, but this (r)evolution risks to sharpen the gap between Large and SMEs. Data is the oil of the future economy, but just a few large companies could afford the investment in terms of platforms and skills. SMEs risk to lag behind the data-driven digital transformation, unless provided with low-cost, easy to use and open instruments.

This blog will present an Open Source platform aimed at filling this gap and supporting SMEs towards data-driven digital transformation by providing an all-in-one solution able to integrate heterogeneous data sources, allowing the development of open-to-all advanced services ecosystems on top of the achieved integrated information space. SMEs could, therefore, equal digital transformation of Large Enterprises by means of a low cost highly configurable solution.

To this end, ENGINEERING has been developing several solutions within the FIWARE ecosystem. This blog will describe the latest developments of two of them, namely the OPC UA IoT Agent and Facility Enabler, materializing a perfect conjunction of Open Source and data-driven applications for the manufacturing industry. The technological descriptions will be also complemented by a testing scenario under development in a didactic factory able to demonstrate the experimental results achieved.

Exploiting Industrial IoT Data from Smart Factories

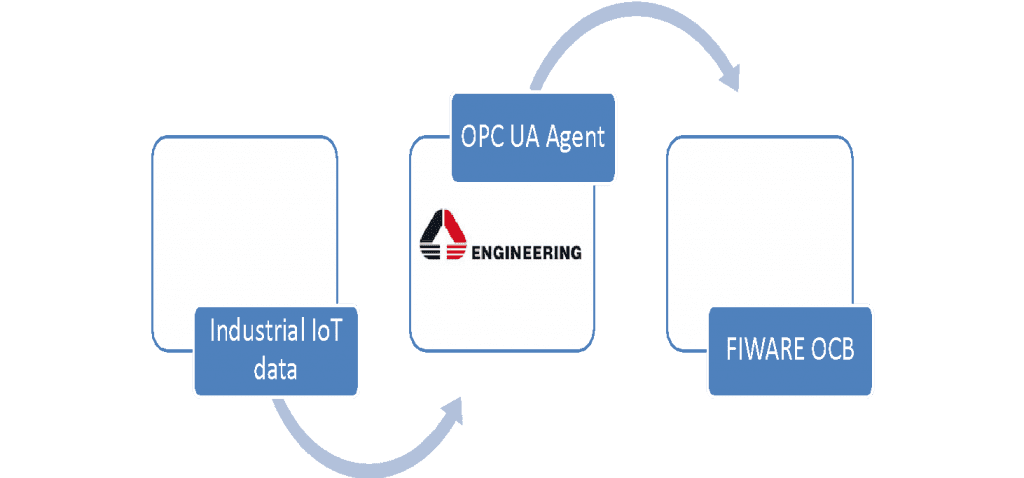

The OPC UA IoT Agent aims to connect OPC UA servers with the FIWARE Context Broker and the Context Information Management OMA/NGSI standard in order to bring manufacturing data into FIWARE, following the RAMI 4.0 specification where OPC UA is listed as the one and only recommendation for realizing the ‘communication’ layer.

Figure 1 – OPC UA IoT Agent Main information flow

The FIWARE OPC UA IoT Agent is able to interconnect Industrial IoT Data in Motion streams coming from manufacturing plants with other FIWARE heterogeneous data sources and datasets. The FIWARE OPC UA IoT Agent will therefore allow the development of advanced “Context Aware” services and Smart Applications needing both OPC UA and OMA/NGSI data sources, such as in the domains of “Predictive Maintenance”, “Supply Chain Optimization”, “Advanced Production Planning and Scheduling” or “Energy Management”.

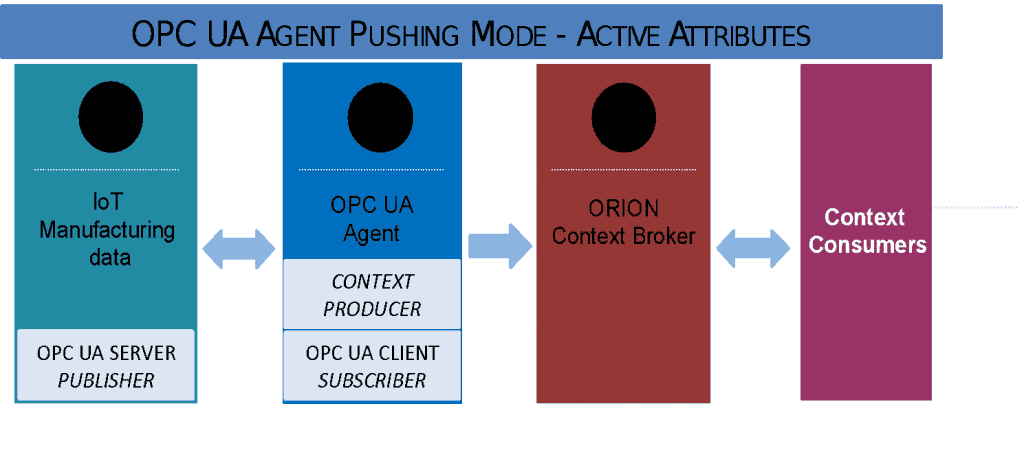

Figure 2 – OPC UA IoT Agent Pushing operation mode

To make the OPC UA IoT Agent operational, it has been integrated within the scope of the Facility Enabler, described in the following, in order to provide an end-to-end solution able to connect OPC UA sources and the processing and visualization capabilities provided by this framework.

Enabling the Factory — Unlocking the Industrial IoT Potential

The “Facility Enabler” is an Internet of Everything platform, powered by FIWARE, for crawling, collecting, integrating, analyzing and rendering scattered data coming from heterogeneous data providers, including sensors, manufacturing systems, and machines. It enables multi-domain data integration, harmonization, and multi-device interoperability. Facility Enabler provides a set of tools to easily develop innovative apps and dashboards relying on the data collected, to monitor, analyze and control complex systems including Industrial plants and urban sensors. Facility Enabler avoids the vendor lock-in for customers and supports fast reuse of apps and dashboards among different customers.

The main functionalities include:

- Data sources discovery from the web;

- Data info collection and quality assessment: Detection of data sources from the web and support in the creation of the “Single Point of Knowledge (SPOK)”

- Devices registration: Possibility to plug-in any device or system through standard protocols (e.g. HTTP, MQTT, AMQP, SigFox, CoAP, OPC UA).

- Data Integration and Harmonization: Possibility to graphically integrate data coming from different data sources and wrap any kind of data structure in NGSI LD FIWARE Data Models.

- Analyze and render data through user-friendly dashboards: Assisted creation of apps and dashboards relying on the data present in the SPOK, that are reusable among different customers.

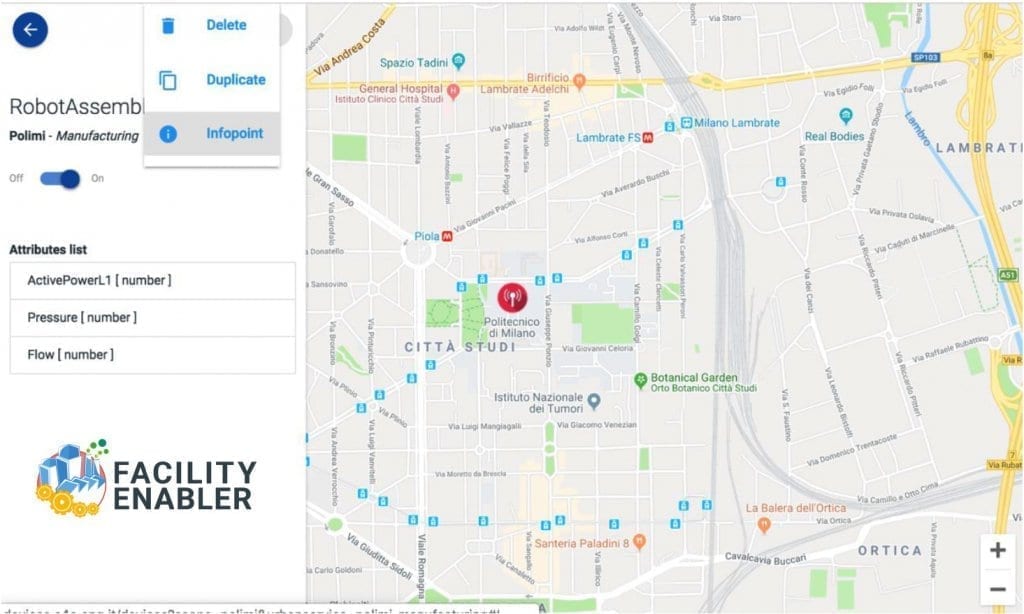

Among the Facility Enabler tools, the IoT Device Manager allows registering devices and industrial systems. It uses the FIWARE IoT agents to communicate with devices and systems, to send commands and to monitor their status.

Figure 3 – Device status monitoring

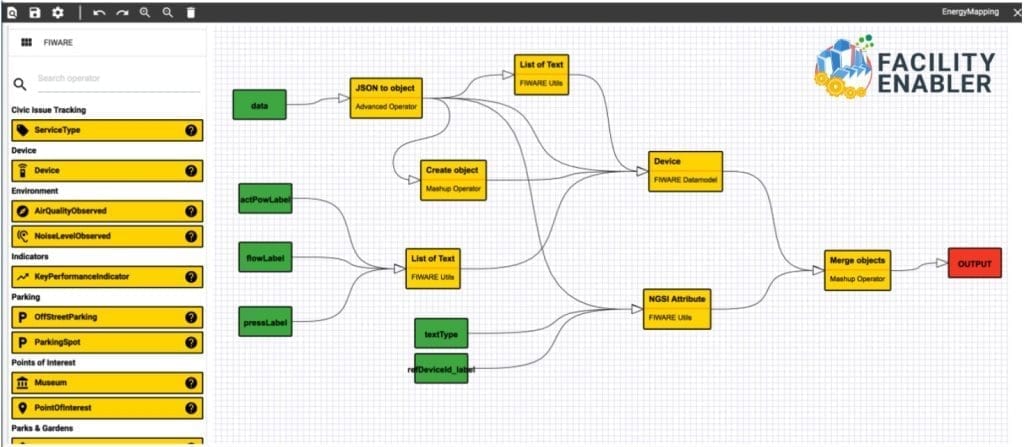

The Data Mashup editor is a key tool of the Facility Enabler. It allows to graphically perform mapping of data structures (e.g. device data, open data, etc..) in NGSI LD FIWARE Data model format in order to enable the creation of apps and dashboards that can be easily reused among different customers.

Figure 4 – Harmonization of data coming from a Manufacturing system in FIWARE Data models

The data harmonized with the Data Mashup editor can be then be visualized through reusable dashboards that allow the monitoring and control of the devices and the exploitation of data. Facility Enabler is part of the same family of enablers provided by ENGINEERING that includes the City Enabler, powered by FIWARE platform.

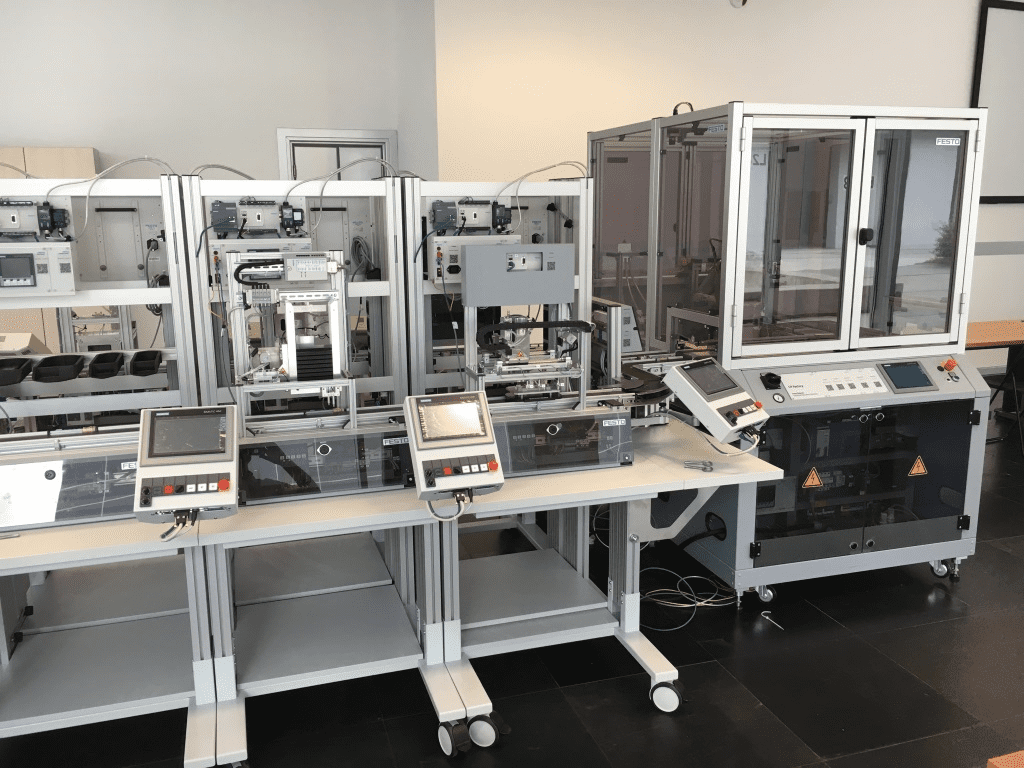

Testbed: Providing Full Control Over The Monitored Production Line

The FIWARE OPC UA IoT Agent has been announced during the Hannover Messe 2018, and it has been already tested and experimented in several scenarios, as well as integrated into other Open Source solutions. To evaluate the integration among the OPC UA IoT Agent and the above-mentioned Facility Enabler, a dedicated testbed has been developed, based on a Didactic Factory powered by FESTO. The experiment setup includes 14 OPC UA servers, installed on 7 working stations and capturing both energy and MES data. The main objective of this experiment is to develop an Energy Management application able to provide a full control over the monitored production line, in order to manage the power status of the stations efficiently while reducing the idle time of machine in favour of standby states (i.e. control the line and turn on a station while the previous station is completing their job).

Figure 5 – FESTO Didactic factory experimental testbed

During the experiment setup, several improvements have been developed on the OPC UA IoT Agent, in order to ease the management of OPC UA source through the Facility Enabler. To this end, the Agent has been provided with a new set of configuration API: using the IDAS API as a starting point, the Agent has been enriched to support the creation, update and deletion of devices managing OPC UA subscriptions. In the described experiment, when a new OPC UA device is registered through the IoT Device Manager, an OPC subscription is sent to the OPC server, so the server will send the data of the sensors to the Agent, who will forward these data to Orion Context Broker (OCB) in NGSI LD format. Through a subscription mechanism, the Data Mashup Editor receives the data, converts it into FIWARE Data Models (i.e. in the experiment by using the Device Data Model) and publishes them in another context of the OCB.

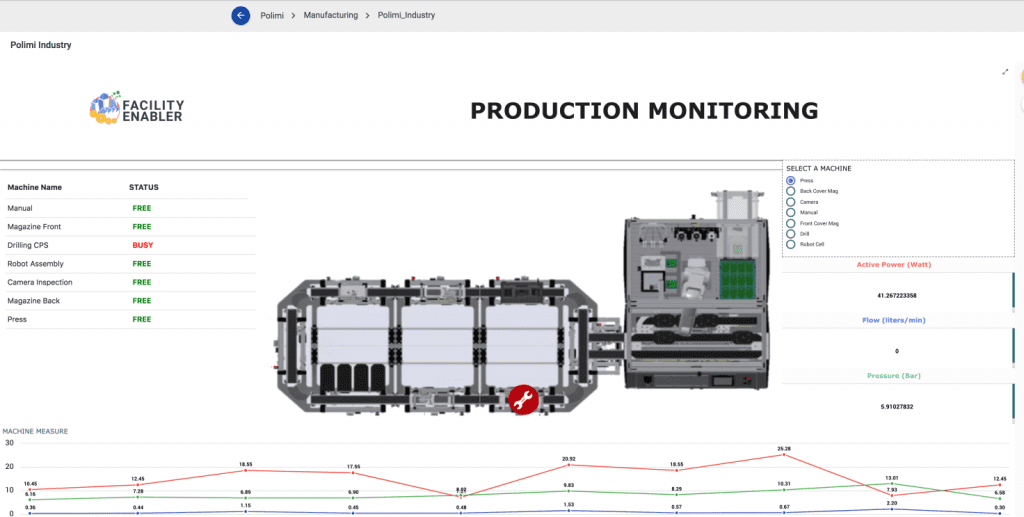

In the following picture, the resulting interactive dashboard designed to monitor the status of the FESTO Didactic factory testing environment is shown. In particular, it is possible to check, in real time, the work status of a piece related to a specific order, the operational conditions of the machine that is working the piece and the current status of some energy parameters associated to each machine (e.g. active power, pressure and air flow). Moreover, historical data are gathered and visualized in charts in order to have a clear overview about the evolution of energy parameters per machine. As the dashboard works with data harmonized in NGSI LD, it can be easily reusable and plugged into other manufacturing application or HMI by creating a new harmonization mashup.

Figure 6 – Dashboard to monitor a manufacturing system that communicates through OPC UA

Guest Post by Angelo Marguglio (Research Area Manager and Head of the “Smart Industry and Agrifood” Unit, Engineering Ingegneria Informatica SpA) and Giovanni Aiello (Project Manager, Engineering Ingegneria Informatica SpA)