Challenge & Context

With the right technology, autonomous manufacturing can offer a new way of looking at production processes giving manufacturers more control over production decisions, less inefficiencies and lower cost alternatives. This is particularly true for customized production lines for customized production lines for lot-size-one or low volume batches utilizing Additive Manufacturing (AM), i.e., 3D printing. The FASTEN project — Flexible and Autonomous Manufacturing Systems for Custom-Designed Products — aims to provide an open, modular, integrated, and standardized IoT (Internet of Things) framework to produce and deliver tailor-designed goods. More specifically, the platform was designed with the ability to function autonomously and deliver fast and low-cost additive manufactured products within the new paradigm of Industry 4.0.

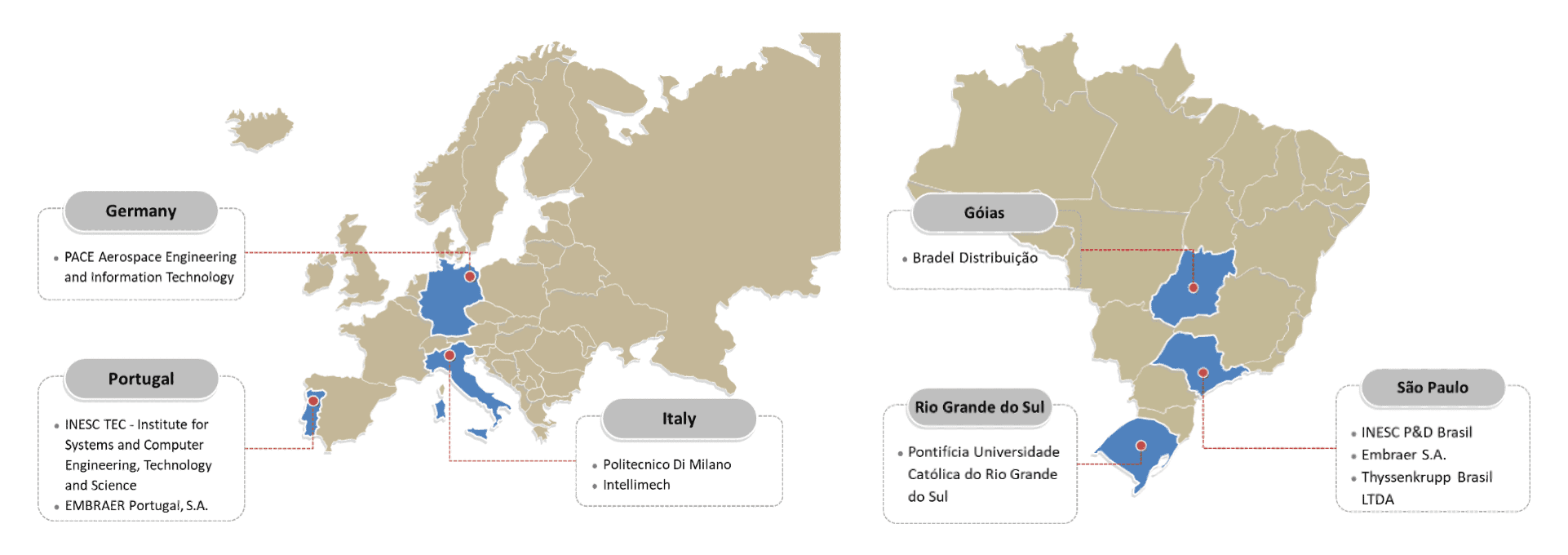

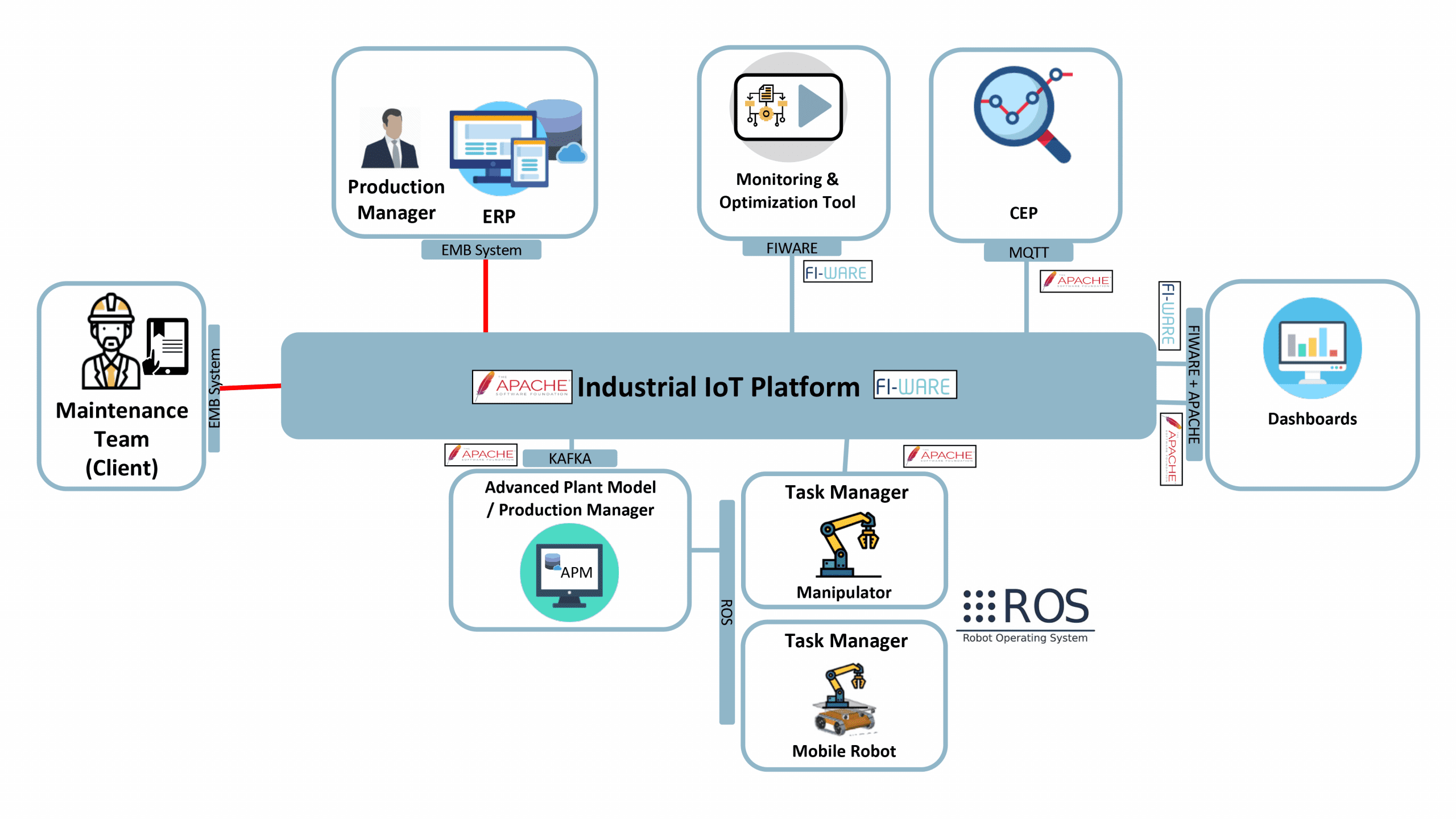

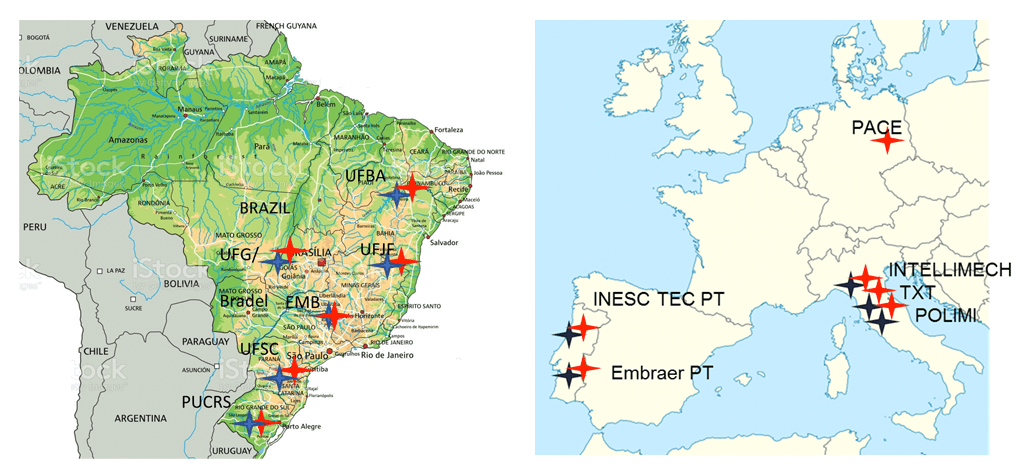

Figure 1 . Eleven partners throughout Europe and Brazil

Eleven partners were involved in the project, six from Europe and five from Brazil. Specifically, the European partners were INESC TEC, Embraer Portugal S.A, Politecnico Di Milano, PACE Aerospace Engineering and Information Technology, TXT e-solutions SPA and INTELLIMECH; and the Brazilian partners were INESC P&D Brasil, PUCRS “Pontifícia Universidade Católica do Rio Grande do Sul”, Bradel, Embraer and ThyssenKrupp Elevadores.

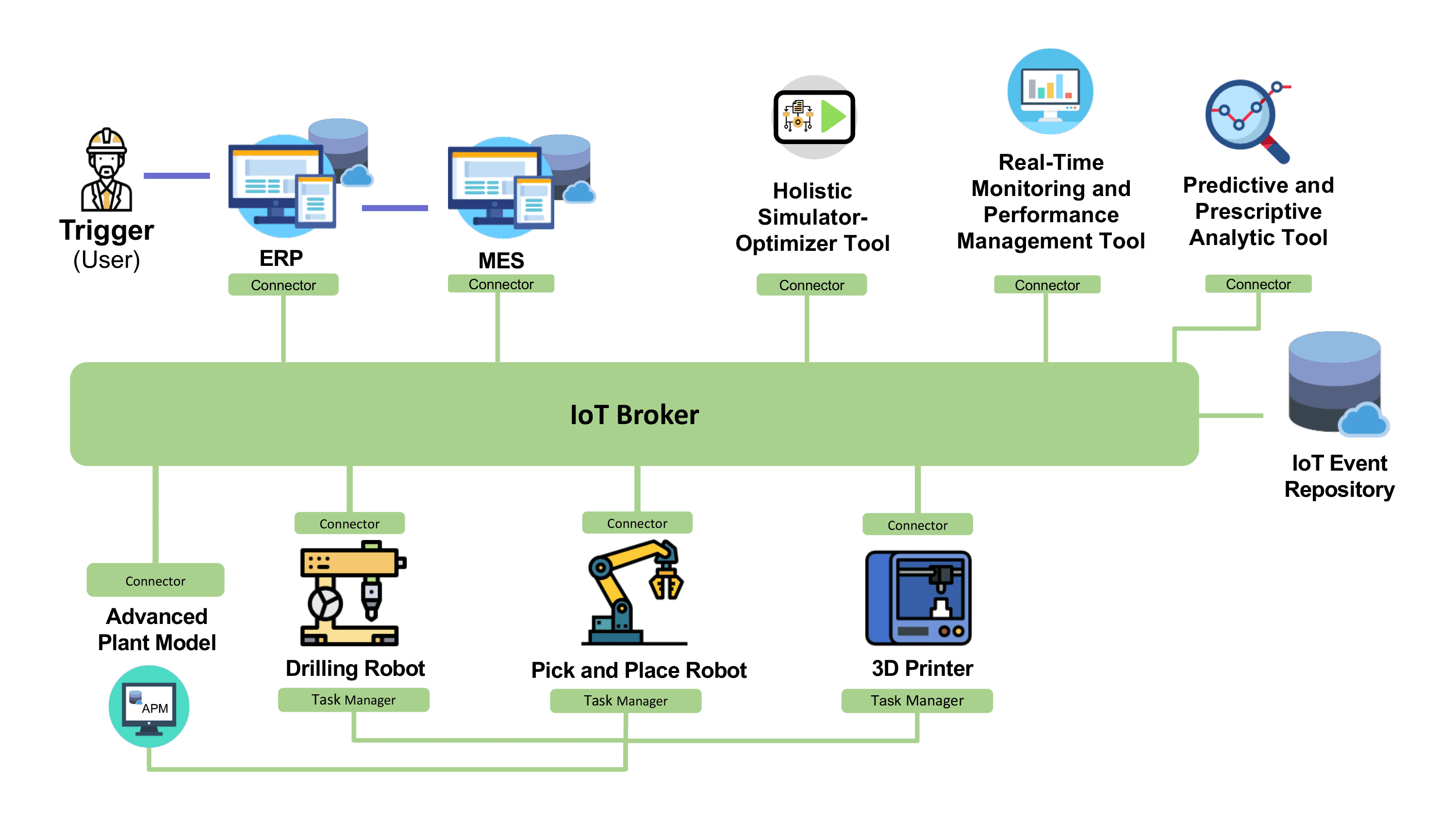

The IoT Platform manipulates data from devices (e.g. robots or sensors) in industrial environments and serves as an intelligent data repository for the optimization and forecasting layer, with the purpose of improving the quality of services offered and meeting the Industry 4.0 requirements.

There are two context-specific challenges: First, the sheer volume of hardware and software elements involved generates an enormous amount of data in a variety of formats. Second, this data needs to be processed and evaluated in a limited time due to the unavoidable uncertainty of industrial environments.

By fostering a common language and understanding the building blocks of Industry 4.0, interoperable systems and interfaces can be developed, and information flows supported. Since Brazil has not developed a similar initiative, FASTEN adopted RAMI 4.0 as a common reference. One of the main requirements of the architecture definition was to be RAMI 4.0 compliant.

FIWARE was selected as the main reference architecture able to meet these requirements. However, project partners decided to compare two different technological solutions for the reference architecture. Along with FIWARE, the project also developed an Apache alternative lane using components from the Apache foundation for IIoT (Industrial Internet of Things) together with the necessary connections and integration software. Namely, Apache Kafka — a streaming platform software — was used as the foundation for this lane.

Using this strategy, FASTEN provided a comparison of implementations between FIWARE and Apache developing the necessary software for both lanes to work together interchangeably.

According to this objective, one of the main technical challenges of FASTEN was to demonstrate the versatility of FIWARE’s European Platform to a varied number of industrial cases, many of them coming from Brazil.

Solution

The trial of the technologies was performed in two FIWARE pilot cases: the first with ThyssenKrupp (TSK) in Brazil and the other with Embraer Portugal (EMBP).

The ThyssenKrupp pilot explored the development of small units able to manufacture outdated and customized spare parts for elevators, in order to meet demand in Brazil, avoiding an excessive number of spare parts in stock and transforming many aspects of the current supply chain distribution. To achieve these goals, AM technologies supported by state-of-the-art robotic automation seem promising solutions. The pilot focused on a Smart Robotic Additive Manufacturing (SRAM) unit composed of a 3D printer supported by robots working autonomously, monitored and guided by the IIoT Broker.

Another important goal of this pilot was to optimally configure the network of SRAM units to ensure the availability of spare parts as fast as possible for maintenance operations all over Brazil — in itself challenging for its size. Therefore, the pilot had to address the integration between back offices and the manufacturing units, such as the verification of parts ordered and improvements in lead-time. Besides robotic solutions and AM technologies, other technologies played an important role, specifically, optimization and simulation tools as well as prescriptive and analytic solutions. The information flow between all these solutions, from the field level to the legacy systems of the enterprise, was built upon the IIoT framework mentioned above.

The scenario in the Embraer (EMB) pilot was different. The manufacturing processes in the aerospace industry still face difficulties with integrating and automating manual operations that need flexibility and adaptability. Although there are some commercially available solutions, performance may vary greatly depending on the range of shapes, sizes and disposition of the parts. It is safe to say that there is no well-defined process for selecting grippers, the perception system, robot degrees of freedom, operation speeds, and algorithms, among many other variables. For each different use-case and environment, putting together a working solution often requires research and development.

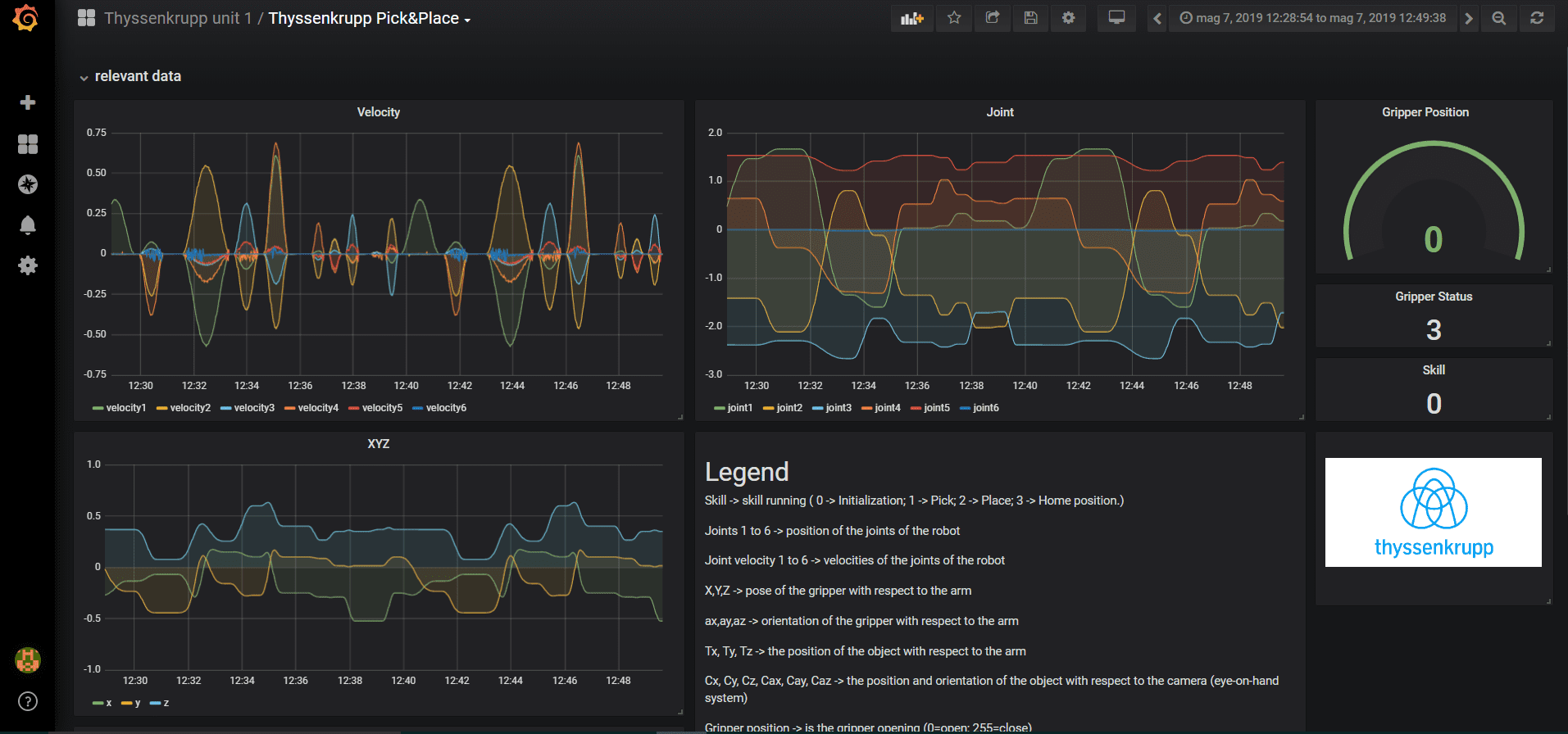

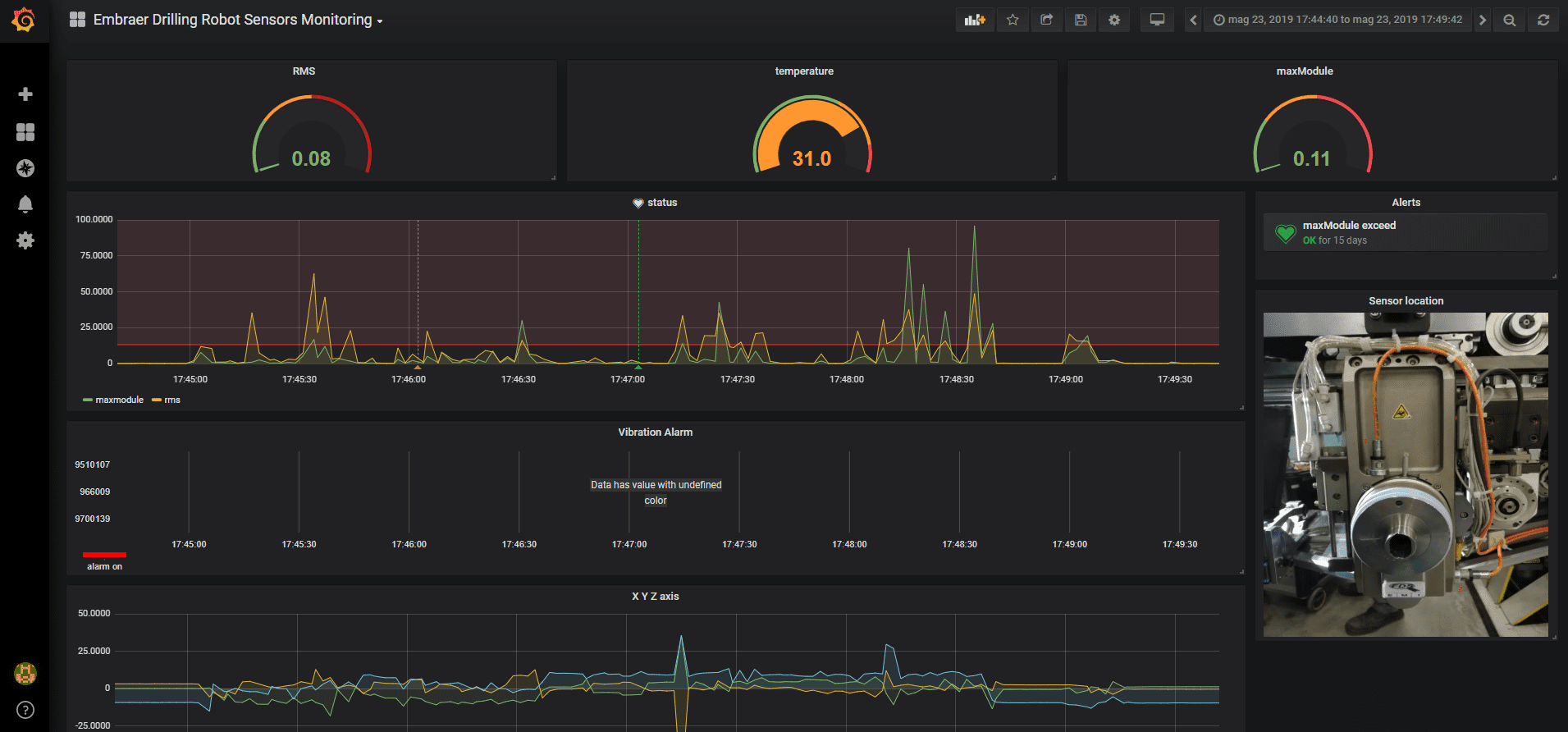

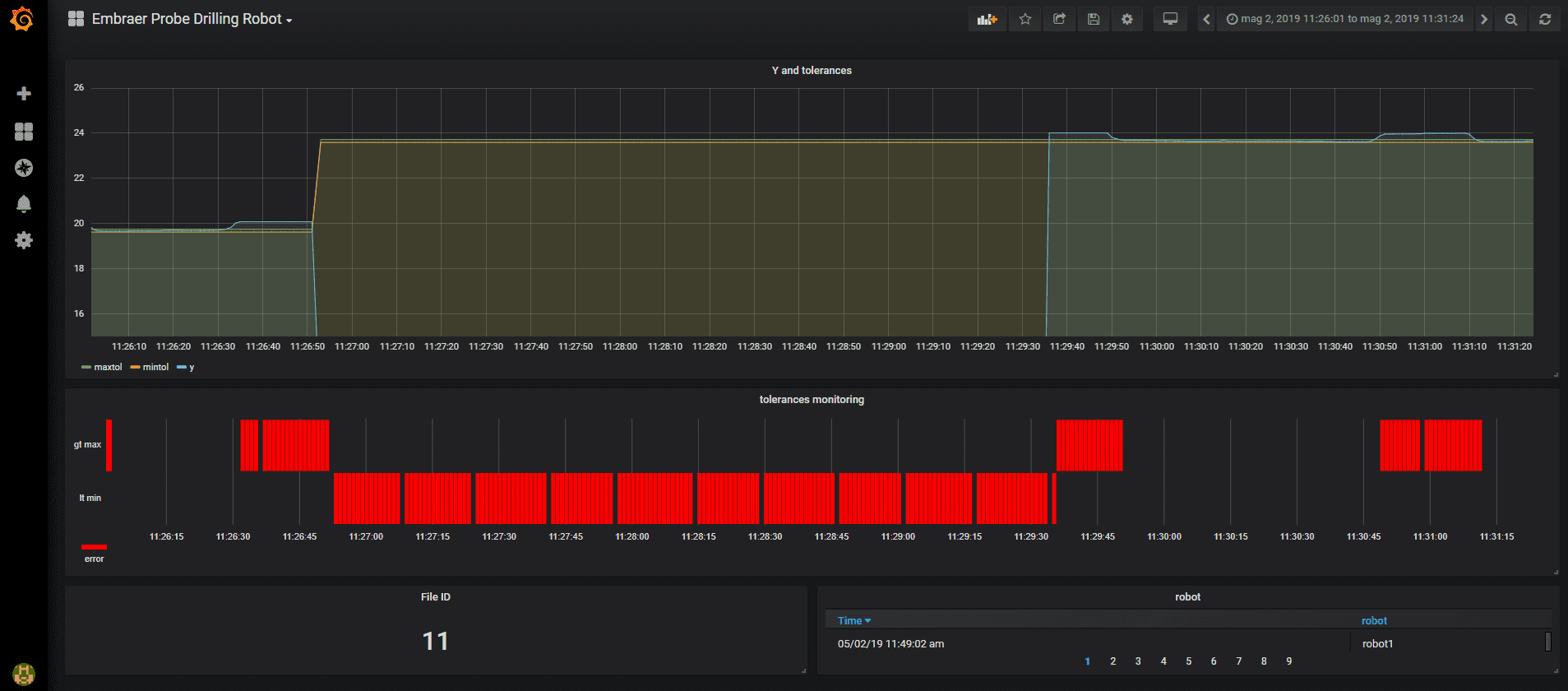

The Embraer Logistics warehouse in the city of Évora, the capital of Portugal’s south-central Alentejo region, is a perfect example of this problem, as it has to manually deal with diverse parts to assemble kits and supply the production areas. In order to automate the kit assembly process, the FASTEN solution wanted to provide a Pick and Place (P&P) Collaborative Robot capable of communicating with other systems, recognizing and handling distinct parts. The information exchange and action coordination happen through the edge side of the FASTEN IoT Platform. The IoT layer enables this integration, real-time monitoring of performance and enhances collaboration to deal with different parts and unforeseen incidents. As such, IoT is also used to enable more efficient collaboration between human operators and managers. Therefore, specifically designed Real-time Monitoring and Performance Management Tools are responsible for consolidating data from the systems and data obtained after monitoring the P&P Robot in the form of graphical dashboards.

How it works

All the interfaces were accomplished on top of Grafana using the time series Database of the underlying IIoT Platform (CrateDB, InfluxDB) following data cleaning and processing.

The Platform is based on Apache Kafka and FIWARE lanes and uses the Swagger tool for API management. CrateDB, SQLlite and PostgreSQL solutions in the provision of data persistence. For user interaction purposes (Interface Layer), the Django Web Framework targets the Embraer use case whilePrimeFaces targets the ThyssenKrupp use case. Both are integrated with the Grafana module, as part of the real-time monitoring tool, for dashboards creation.

Figure 2 . Architecture

The data processing layer is supported by the Django or Flask based systems and involves:

- Python libraries (Numpy and Pandas) for the data preparation layer;

- Scikit-learn and the Keras libraries for Machine Learning;

- StatsModel for the forecasting models.

The use cases have tested different combinations of these technologies. For instance, the TSK application uses Primefaces, Flask, Swagger, Kafka and PostgreSQL, whereas the Embraer uses Django, FIWARE and SQLite components.

ThyssenKrupp Solution

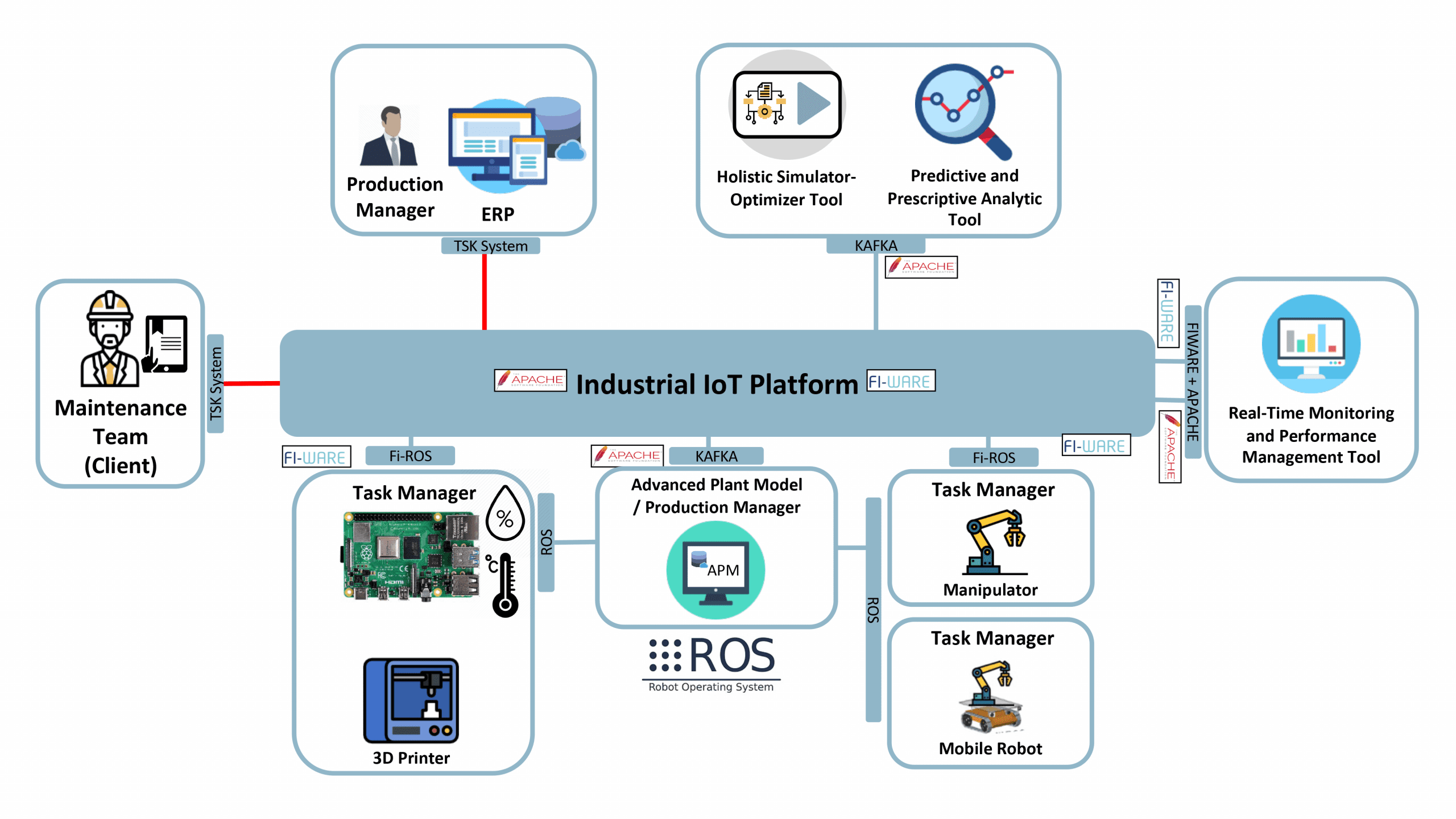

Figure 3 . ThyssenKrupp Application

A fully hybrid FIWARE and Apache architecture was designed and implemented. The various unit modules are developed in ROS and communicate with the FIWARE lane through FIROS. Each of the FIWARE lane major components (Orion Context Broker, Quantumleap, CrateDB and Grafana) were encapsulated in a Docker container. The data emulation is done by running different Python scripts that read various log files generated by the real SRAM and then send messages and data to the Context Broker using the RESTful APIs. Information is aggregated and then represented on dashboards.

The remaining part of the system, which enables optimization and simulation as well as analytic actions, works with both lines: the Apache line for the integration with the Simulator-Optimizer tools, and FIWARE for the integration with the SRAM.

Figure 4 . ThyssenKrupp Pick and Place (P&P)

Embraer Solution

A hybrid platform was then created: an Apache solution for the P&P part of the system and a FIWARE solution for the monitoring/optimization one.

Figure 5 . Pick and Place (P&P) hybrid platform

In the P&P part of the system, robots are connected to the IIoT platform via the MQTT broker and the Ros2MQTT bridge, consequently two main services are provided. The first one saves the raw data in a predefined structure into a database to make it available for the Monitoring/Optimization tool. The second service is provided by Complex Event Processing (CEP) modules, which have been developed to process the incoming raw data streams thus generating alarms or notifications.

Figure 6 . Dashboard (1)

The monitoring/optimization part of the platform uses FIWARE. The Platform is composed of: the Orion Context Broker, Quantumleap, CrateDB, a MODBUS-RTU interface, CEP Module, and Grafana. Orion Broker can dispatch NGSI2 messages between the Monitoring/Optimization Tool, the Dashboard and the end-points. Data stored in the DB can be presented through Grafana in different dashboards. Furthermore, CrateDB stores the KPIs calculated and Grafana displays these KPIs in the form of dashboards. FIWARE lane is then composed of: Orion Broker, Quantumleap, CrateDB, a MODBUS-RTU interface, CEP Module, and Grafana.

Figure 7 . Dashboard (2)

Benefits & Impact

FASTEN stands out from the competition considering its integrated framework for Smart Manufacturing. Consisting of lot size one manufacturing, decision-making for real-time actions, integration of robotic and additive manufacturing technologies, higher levels of connectivity, and real-time simulation and optimization, combining machine learning with simulation-optimization approaches.

FIWARE and APACHE solutions are used for low cost data gathering from machineries and other smart objects, low level data management (e.g. complex event processing, context management and alarming) and storage/reporting. This open source approach supports the implementation of a new offering for non-high-spending customers not intending to use high-end commercial solutions. The project enabled a scale up from single open source solutions to an integrated set of Docker/Kubernetes containers which can be quickly deployed on premise or in the cloud dramatically decreasing the cost of the overall project. Specific attention has been placed at a commercial level in positioning this offer in order not to cannibalize the traditional high spending business:

- APACHE open source approach is presented to low-spending companies as best alternatives to follow, and based on one of the best solid open communities in the world with solid documentation and industrial references;

- FIWARE is used for big(ger) customers as a tool for quick proofs of concept to evaluate new processes which will be replaced by IIoT systems from the market and supported by certification programs together with software liability.

From the achievements of this project, EMB hopes to increase productivity levels and to modernize the production methodologies employed, improving the responsiveness it can provide to its customers. Using robotics and intelligent systems, flexible production lines are enabled. Consequently, cost reduction and additional product customization is an expected next step for future implementation. For TSK, the adoption of FASTEN validates its initial objectives, which were the improvement of maintenance service levels, spare part lead-times, manufacturing and inventory costs. Moreover, advanced additive and robotic manufacturing technologies allow a flexible integration among production, logistics, transportation, and material handling processes. TSK’s ambition is to gradually apply Additive Manufacturing innovations, which could lead to a more responsive maintenance support program achieving higher adaptability, in response to market demand in the complex and wide market including many business opportunities in South America.

Besides the technical aspects previously described, an important result of the project was the utilization of FIWARE in the industrial domain out of Europe, especially in Brazil. More than 10 industrial and research implementations of APACHE/FIWARE architectures have been carried out, seven of which were developed in Brazil.

Figure 8 . Industrial and research locations

Added value through FIWARE

FIWARE provides a technological shortcut to efficiently implementing any IoT solution, sometimes with a trade-off on the customisation options provided by other platforms such as Apache, for instance. FIWARE-based solutions can be an effective PoC (Proof of Concept) or employed in circumstances where resources are an issue or customisation is unnecessary. Vice versa, expensive Apache-based systems are, today, still the leading choice for commercial solutions and custom implementations.

The benchmarking comparative study of the Apache and FIWARE IIoT platforms has shown that both implementations can equally comply with Industry 4.0 architectural requirements. The IIoT reference architecture was proven to be generic enough to be used as a blueprint for integration and adaptation to working systems in a real industrial context. Therefore, the choice for one or the other implementation depends on the use case and a potential customer’s system environment.

FIWARE use was particularly appreciated in Brazil where it is now used or taught in numerous universities and research centres.

References

- FASTEN

- Presented at the FIWARE SMART FEST 2021: FIWARE Smart Industry session, June 8th, 2021