Challenge & Context

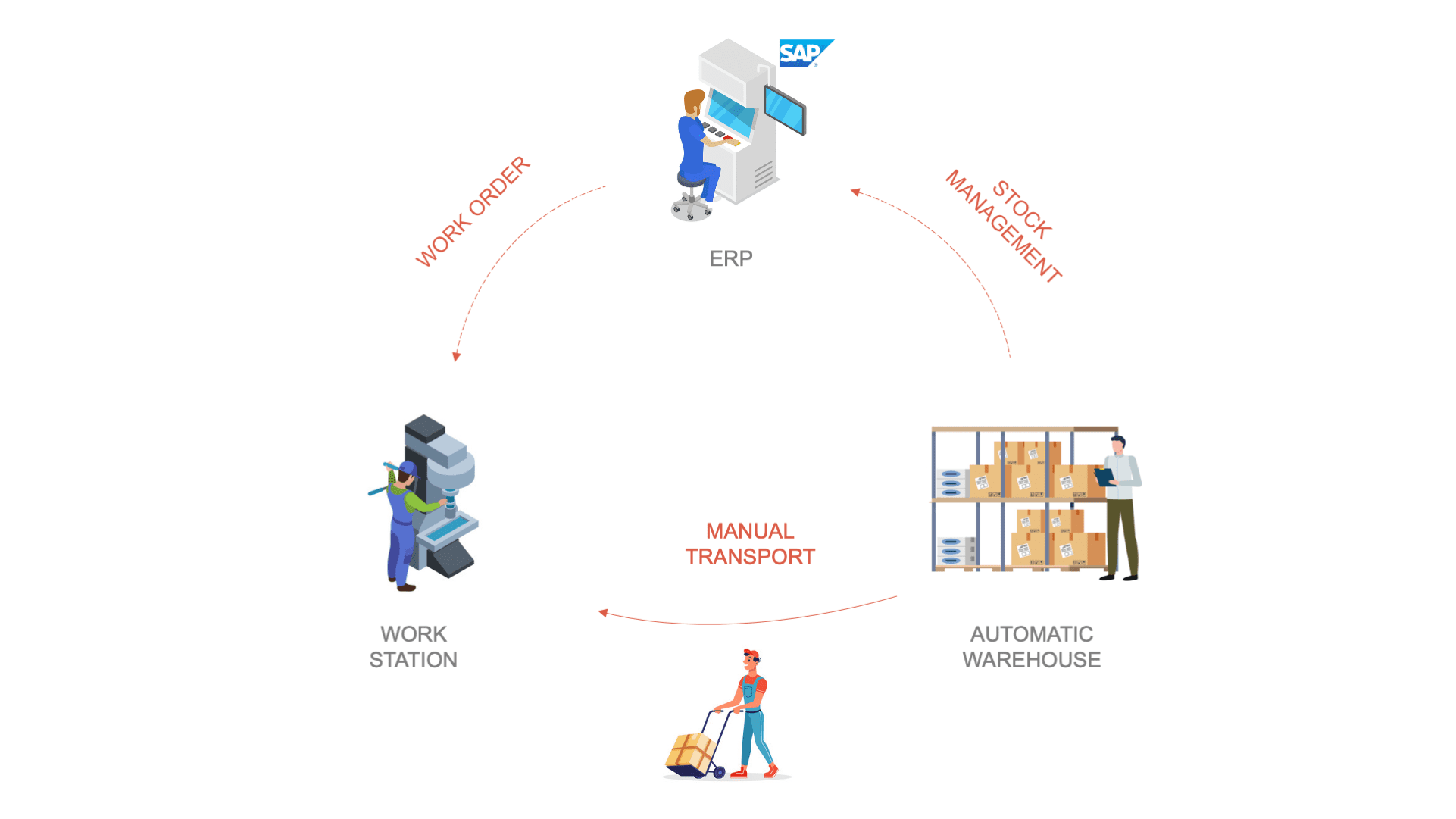

Warehousing and logistics companies are increasingly looking to innovate productivity and reduce reliance on human physical labor with the use of robotics automating the processes that are the most physical and labor-intensive. Currently the transportation of raw materials between warehouses and various workstations is still executed manually in most small and medium sized production centers.

Figure 1 . Durit Production Center

This lack of automation causes an enormous loss of time for workers and prevents production centers from organizing transport operations efficiently.

This was the situation in Durit, a company developing and producing precision tools and engineering components made from tungsten carbide. A typical day in Durit’s production center would begin with the production process supervisor who would compile a list (on paper) of the daily work orders and communicate this verbally to each respective workstation operator. After speaking with the process supervisor each operator would need to manually transport the necessary raw materials (which would involve walking to the warehouse with a trolley, loading up the trolley and bringing back the raw materials to their work stations). This created an increase of people walking back and forth to the warehouse causing unnecessary traffic on the shop floor and in the warehouse where the operator would need to wait for his/her turn.

Furthermore, to avoid going to the warehouse several times in a specific period, operators sometimes pick up enough raw materials for several work orders simultaneously which led to work order errors in the past from confusing raw materials collection. At the warehouse, the warehouse operator is responsible for retrieving the requested material and placing it on the trolley the workstation operator carries. This request of material and respective quantities is also done verbally by the workstation operator and so, also during this stage, there might be errors and confusion. At the end of the day, the list of work orders is “closed” by the process supervisor after he/she confirms all the work completed together with each individual workstation operator.

Durit proposed to DALMA ROBOTICS (Dalmasys Lda.), Porto (Portugal) fo find solutions for the challenge of automating this workflow, which has given rise to the innovative FIWARE-based solution for intralogistics – known as FEATS (FIWARE-Enabled Autonomous Transportation System). The automation solution provided by FEATS has a direct impact on the first step on the production process, namely the work carried out by the workstation’s operators, but it also has an indirect impact on the following steps:

FEATS solves the problems associated with a lack of means to communicate, monitor and analyse intermediate production milestones, which typically leads to schedule deviations and suboptimal working plans for every step of the production cycle.

The implementation of FEATS did not imply the elimination of any workstation (exclusion of any collaborator), which is an important fact Rather, it enabled the operators to stay at their workstations and focus on their main activity of manufacturing semi-final products. In summary, the smart logistics solution implemented at Durit enabled:

- elimination of communication errors;

- elimination of workstation downtime;

- elimination of use of improper materials;

- decrease of traffic on the shopfloor and warehouse-less interaction between people

- manufacturing process synchronized with ERP system and automatic warehouse-scheduled actions;

- real time visualization and management of all transportation tasks;

- log of all automatic actions – accurate calculation of relevant KPIs such as: time spent on transport tasks [man.h/day]; downtime of workstations [man.h/day]; number of times an incorrect material is used at a workstation.

Solution

As a Smart Intralogistics Service, the main purpose of FEATS is to automate the transport of raw material from the warehouse to different workstations. To that purpose, it contributes the necessary features to easily integrate ERP systems, automated warehouses, and autonomous transport robots and provides the user with a simple app that allows the 24/7 supervision of automated transport operations from everywhere.

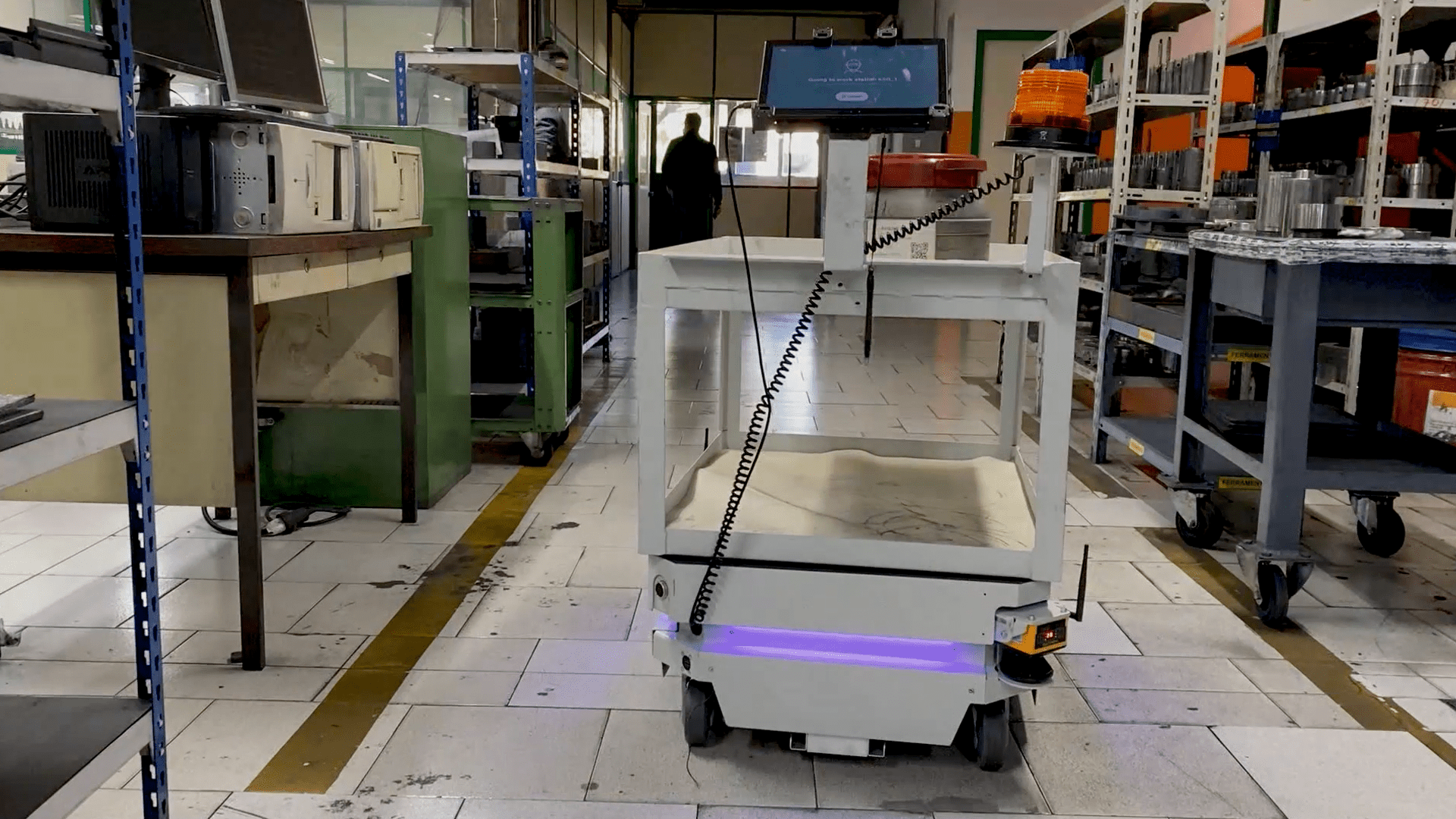

Figure 2 . Raw Materials Trolley

Fortunately, Durit was already working with an ERP system (SAP) and an automatic warehouse and so, together with DALMA’s transport autonomous mobile robot (AMR), the necessary equipment was readily available to implement a Powered by FIWARE Solution. This new solution enables the entire raw material transportation process to be automatic and autonomous and digitally connects the following three components to the FIWARE Context Broker through convenient system adapters:

- The AMR, which is a mobile robot with the distinctive characteristic of being 100% autonomous to safely navigate the environment (i.e. it does not need marks, beacons, or external hardware). In FEATS, the role of the AMR is to guarantee a proper and autonomous delivery of raw materials to the manufacturing production lines by picking it up at the warehouse and delivering it to the different workstations;

- The Automatic Warehouse, which is a vertical automated storage and retrieval system ( Modula is the specific one being used by Durit). Its main role in FEATS is to control all material movements and stock and guarantee proper and on-time delivery of raw materials to the AMR;

- The ERP System (SAP), which is, in turn, responsible for the coordination of work orders taking into account the company’s needs, the manufacturing processes and the material availability at the warehouse.

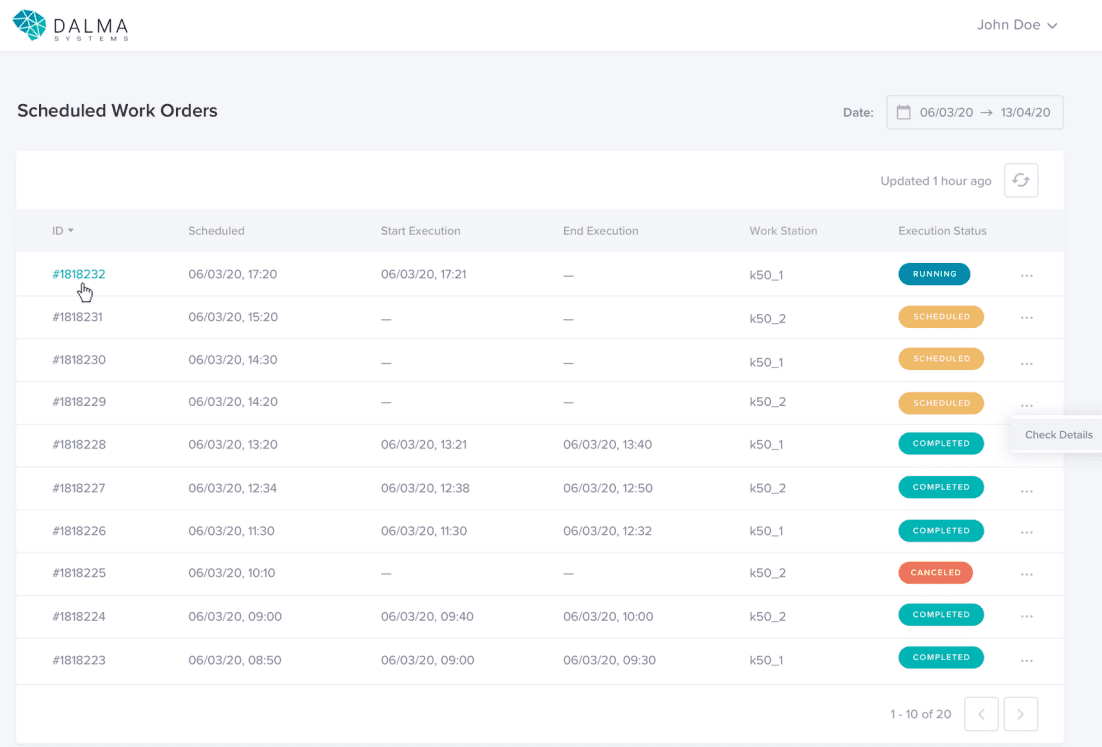

Besides the automation systems, the solution considers three user interfaces (UIs) for the real time visualization and control of the transportation processes:

- The supervisor UI lists the information of each work order (WO) of the day — information received from SAP: ID, scheduled starting time, real starting and ending times (done by the AMR), workstation where the material is supposed to be delivered and the WO status (running, completed, paused, cancelled). The user can interact and control the system using this UI;

Figure 3 . Scheduled Work Orders

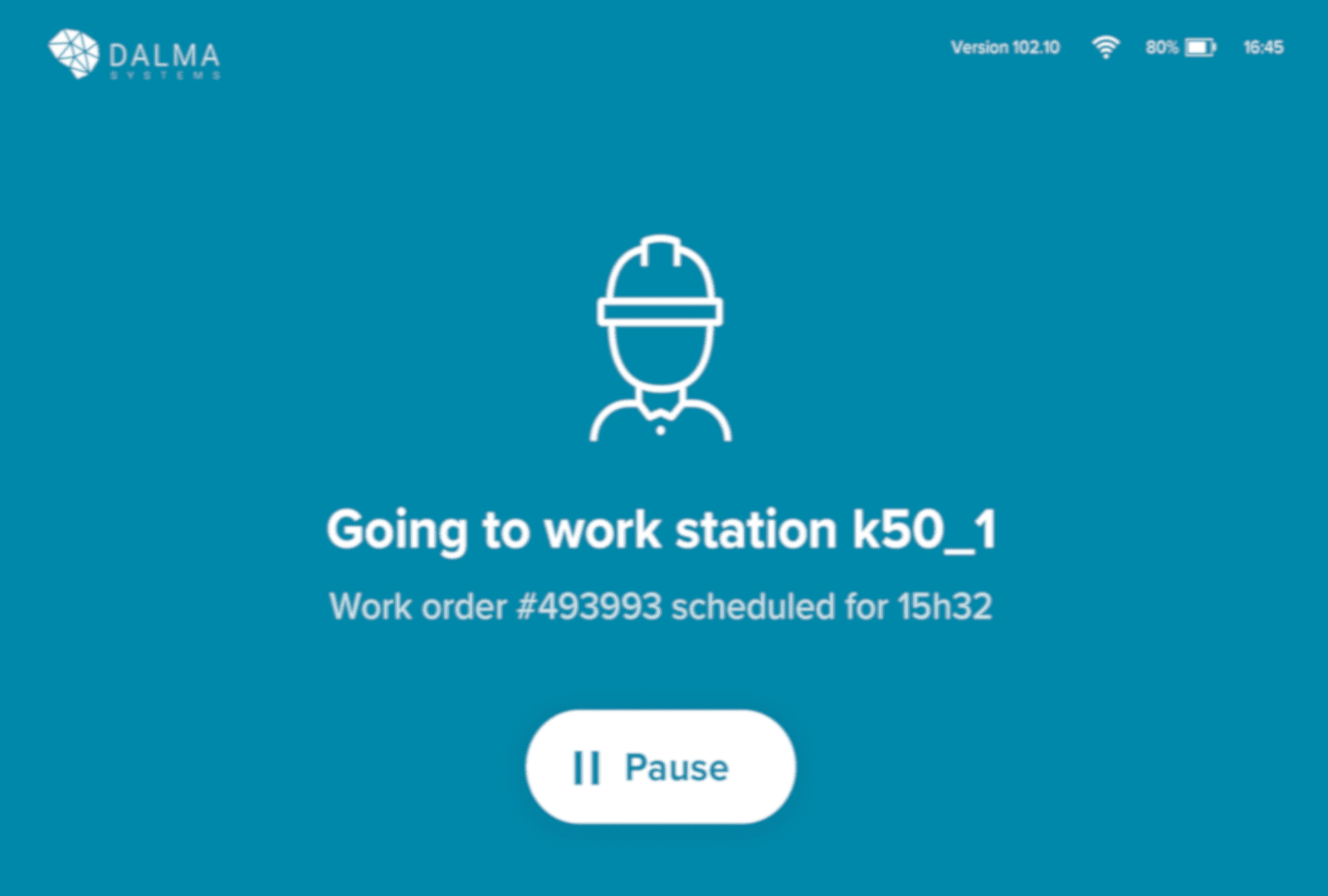

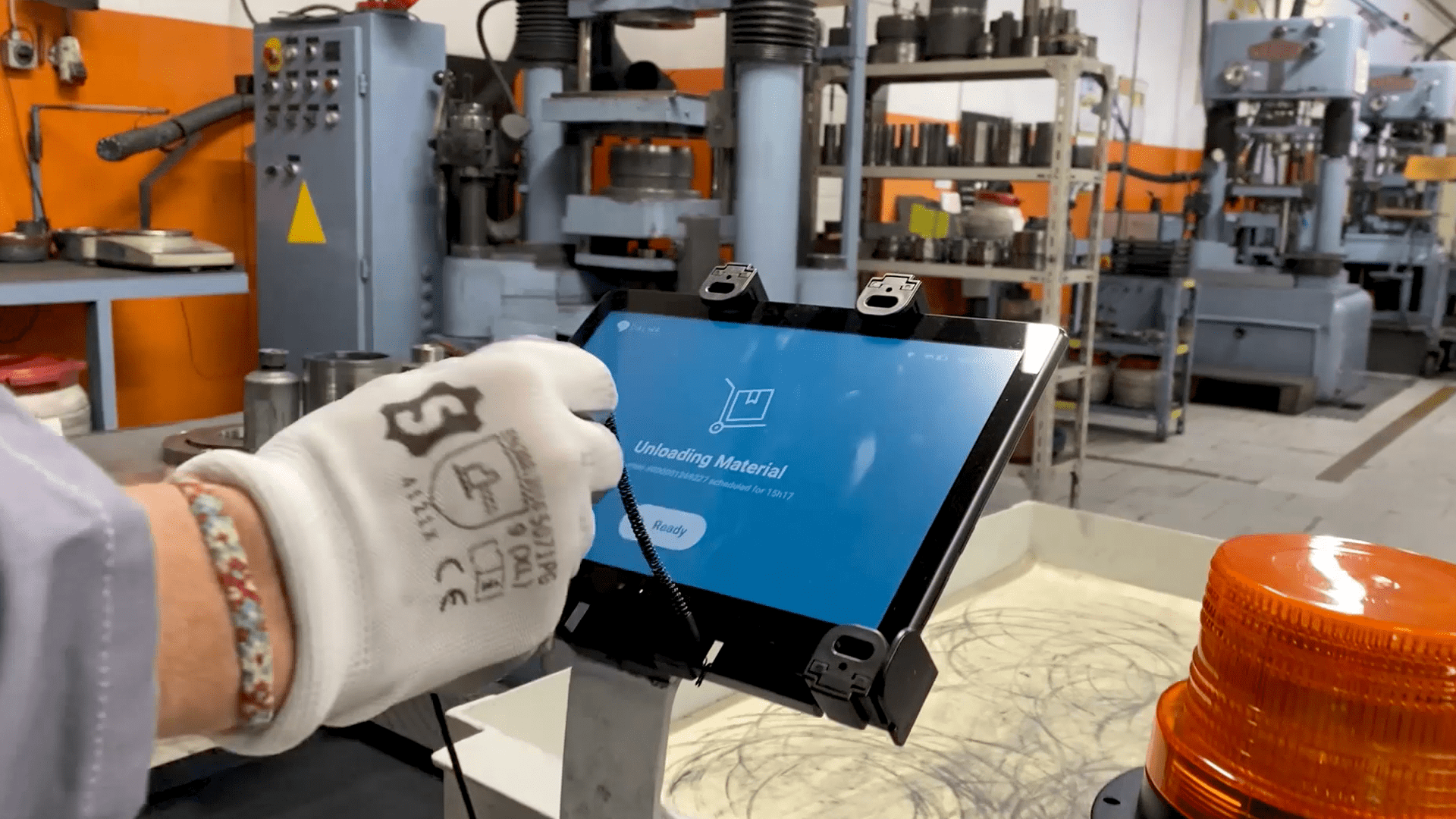

- The robot UI is installed in a tablet fixed in the AMR’s structure and it shows the status of the AMR, namely: status — what it is doing (goal), ID of the work order it is completing, battery level (in %), wifi connection level and current time. In order to guarantee the progress of the transport tasks, the user needs to click on the “ready” button of the robot UI when he/she has completely loaded/unloaded the robot;

Figure 4 . Programmed Work Order

- The warehouse UI is a copy of the supervisor UI without the AMR widget and without permissions to interact with the FEATS system. Thus, the warehouse operator can only monitor the work orders and their details, but he/she is not able to manage them.

How it works

The FEATS solution allows Durit’s ERP system, Durit’s automatic warehouse and DALMA’s autonomous mobile robot to communicate using the same standard language.

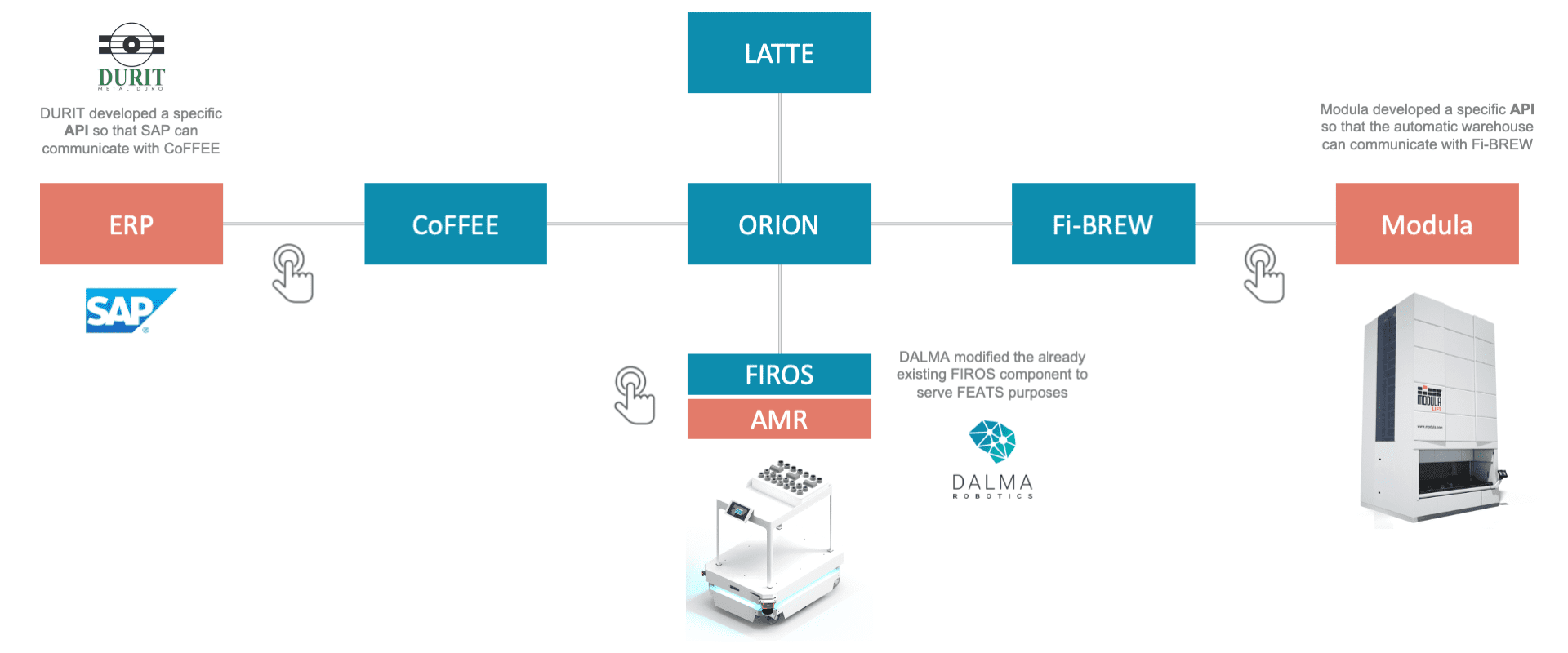

The use of the NGSI API and FIWARE’s open technology significantly facilitated the design of such a modular and interoperable system. This was achieved in the FEAST project through the use of four FIWARE-ready components: CoFFEE, Fi-BREW, FEATS Agent (which is based on the existing FIROS component) and LATTE (the smart data service). All were fully developed by DALMA shown in blue boxes in Fig. 5. Besides these FIWARE-ready components, some extra APIs were developed to enable communication with the third parties’ systems, represented in the orange boxes in Fig. 5.

Figure 5 . Connections through Orion Context Broker

Typical Workflow

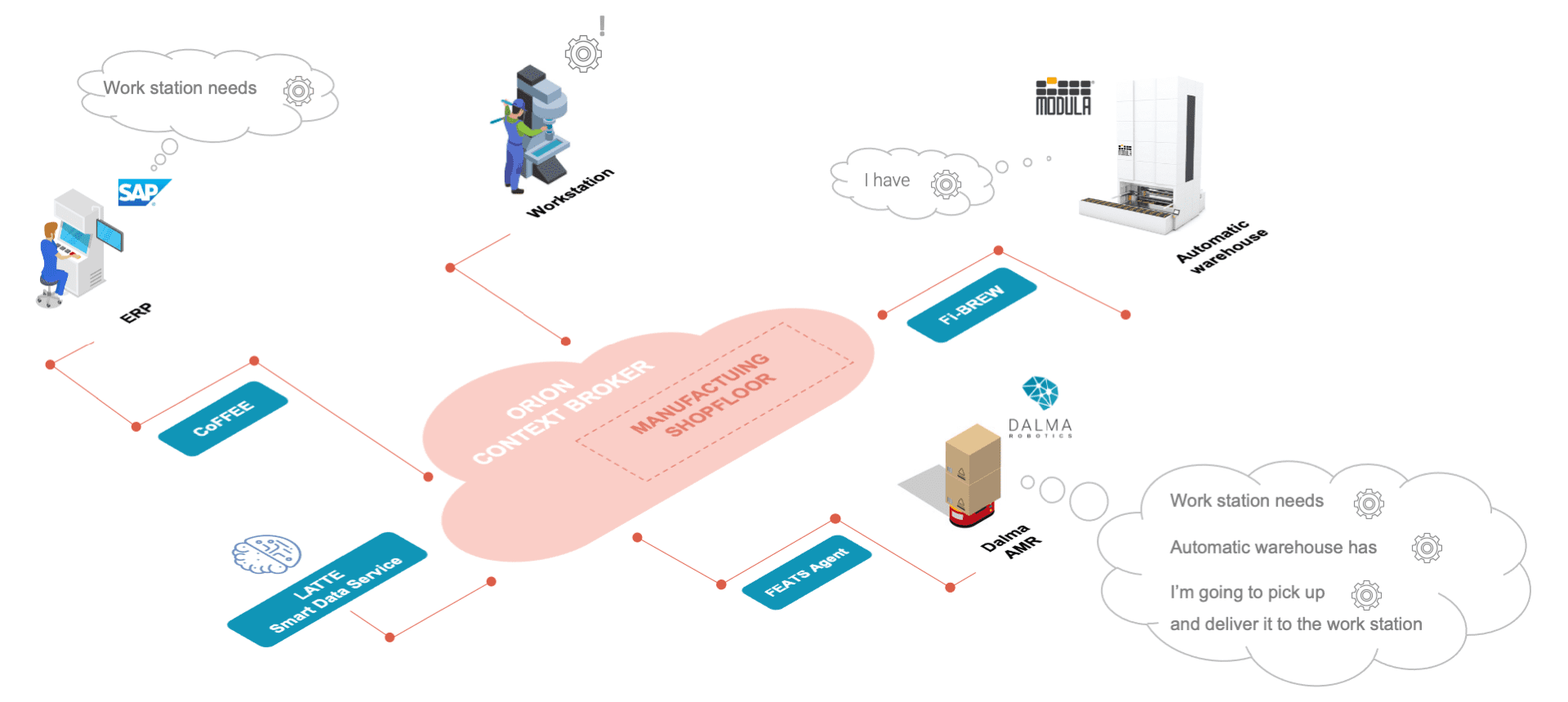

SAP releases the work orders for the day. This information is published on the Orion Context Broker through CoFFEE. Instantly, all remaining systems are aware of this information since all other FIWARE components subscribe to the information published. The automatic warehouse receives the information though Fi-BREW which informs the warehouse which material, batch and quantity is requested to be made available at a specific time and the Autonomous Mobile Robot receives the information through FEATS Agent which informs the robot that the requested material will be available at a specific time at the warehouse and needs to be delivered to a specific workstation. But neither one actually takes action immediately. It is LATTE that triggers the actions based on the information provided by SAP and the information received from the warehouse and the robot regarding their own statuses.

Figure 6 . Communicating through Orion

The minimum human action needed during all the process is the manual loading and unloading of material on/off the AMR and clicking the “ready” button of the robot UI (installed on a tablet permanently fixed to the AMR) when the loading/unloading is completed. Order actions such as pause / cancellation / abort / resume can be done by the supervisor using the respective UI, in case of need.

Figure 7 . Robot UI Tablet

Benefits & Impact

FEATS has had a huge impact on DALMA’s growth in all aspects, it is mainly thanks to this solution that a strong relationship with Durit has been established. Durit has been using the FEATS system from the beginning and has now requested the evolution of the current version of FEATS to achieve more advanced levels of automation. Some improvements and possible extensions that are currently under consideration include:

- extending the solution to other production departments;

- transporting material within the same facility and between two different facilities — indoor and outdoor paths;

- adding load cells to the AMR so it can automatically identify when the expected load for each work order is reached and so proceed with the task. This will free the warehouse operator to click on the “ready” button of the AMR interface in order to give orders to proceed;

- adding to the capability of the AMR to read the material containers’ RFID/QR codes to automate the identification of the goods to be transported, directly communicate stock changes to the ERP system and track the goods in real time within a specific facility;

- Adding to the capability of the system to also consider return of materials from the workstations to the warehouse;

- adding a robotic arm or a belt conveyor on the top of the transport AMR to automate the loading and unloading of material to/from the AMR.

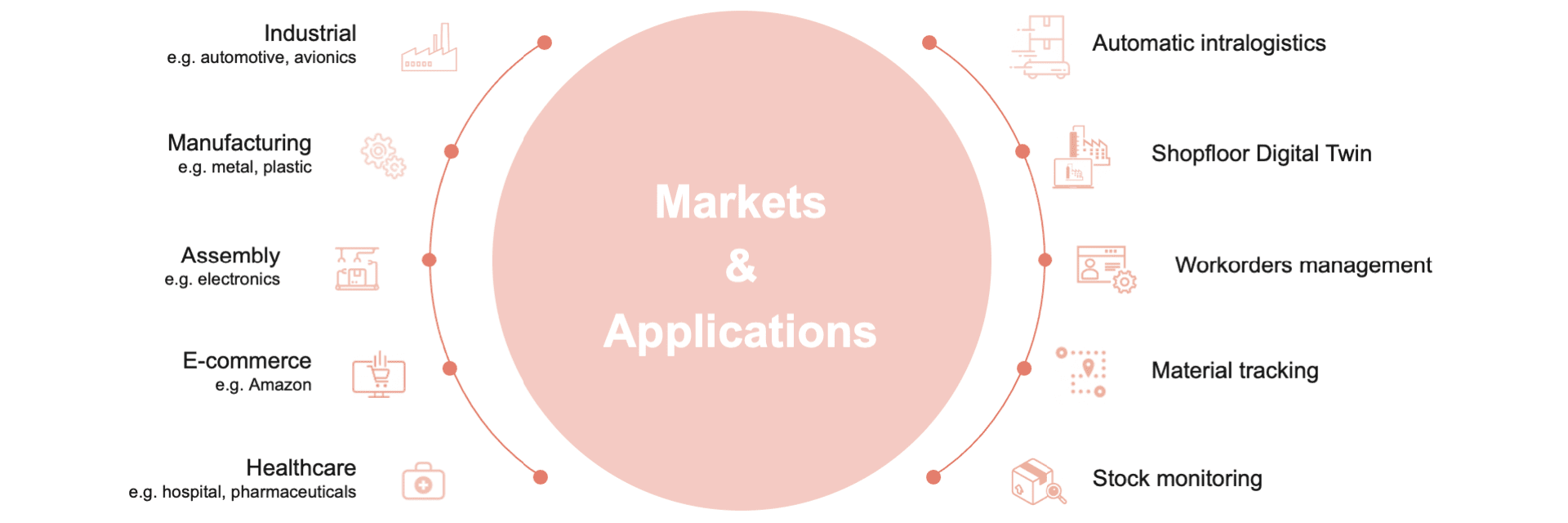

Durit’s use case has proven to be the perfect showcase for also other potential customers. FEATS, as a Smart Logistics Service, and/or as individual components can be used in various market segments and applications, as shown in Fig. 8. Furthermore, DALMA is already working to make FEATS operational in outdoor scenarios, which will allow the company to reach an even broader market. So far, DALMA has already been approached by other international companies interested in acquiring a similar solution. These companies include:

- an avionics company, manufacturing precision parts and mechanisms, interested in the transport of milling tools from their tools warehouse to their various CNC machines. All transportation activities would be connected to their Tools Management System (acting as an ERP system);

- a plastic injection company working for the automotive market wishing to automate the transport of finalized parts from their different workstations to the warehouse;

- a private hospital looking to automate the transport of towels, clothing and medicine between several hospital floors by using the service elevator.

Figure 8 . FEATS current and potential Markets and Application

Added value through FIWARE

One of DALMA’s core values is the democratization of new technologies — in particular robotics, so that smaller companies can compete on the same playing field as larger companies. As a startup, having access to open-source software has been vital in saving time and therefore enabled an acceleration of the development process. From a customer’s perspective, it is also much easier to implement technology and products from different tech suppliers if there are open-source components available for tech providers to adapt their products to different realities and standardize communication among different systems/equipment within the same company.

FIWARE has been crucial in designing FEATS as it enables the addition of new components without the need to dismantle system aspects. FIWARE makes use of standard APIs and harmonized data models making DALMA’s solution a very flexible and scalable one. DALMA’s future plans include implementing and/or expanding infrastructures with new and current partners and continuing to add new features and ideally contribute to the expansion of FIWARE as a global and standard platform.

FEATS project has been responsible for DALMA’s first contact with FIWARE applications. The FIWARE community is making a great effort to standardize the way through which users interact with data specifically for European SMEs, which further reinforces users to develop open-source software.

Next Steps

While this document was written, right after the DIH² program ended, FEATS had already achieved one company successfully using the system and two others interested in acquiring it. FEATS potential and advantages are clear to companies in different market segments as is the growth and expansion potential of the system. Besides the examples listed above, other system expansions are being considered in the coming months to complement DALMA’s robotic and autonomous solutions:

- extending the solution to other production departments;

- transporting goods between different facilities — outdoor path — navigation using GPS;

- adding load cells to the AMR enabling it to automatically identify when the expected load for each work order is reached.

References

- FEATS promotional video

- FEATS GitHub repository

- FEATS step-by-step tutorial

- The DIH² Project funded the development of this solution as well as

its experimental execution