Challenge & Context

Global trade creates big opportunities and bigger challenges. A streamlined supply chain is vital for a smooth flow of goods. Logistics as a sector plays a critical role in defining the domestic and international competitiveness of any economy.

In the supply chain, multiple stakeholders manage their operations and information independently. This lack of streamlining leads to reduced workflow planning eventually causing delays in the container movement.

In recent years, a growing number of manufacturers and retailers have adopted the supply chain view to manage their businesses. Information and Communication Technologies (ICT) play a key role in this process, assuring the linkages between chain participants as well as a more effective control of time, cost and quality of the service rendered.

The Government of India represented by National Industrial Corridor Development and Implementation Trust (NICDIT) and Japanese IT major NEC Corporation, collaborated to form a joint venture named DMICDC Logistics Data Services (DLDS).

The objective of DLDS is to effectively leverage ICT across the Indian Logistics Sector, providing best practices across the various processes and work towards efficiency in the supply chain. The company aims at bringing visibility and transparency in the logistics environment, streamline the operations across the supply chain and help in the government’s plan of improving the Ease of Doing Business (EoDB) in India.

The flagship product of the company, called Logistics Data Bank System (LDB System), is an overarching solution that integrates the information available with various agencies across the supply chain to provide detailed real-time information within a single window. This trailblazing solution provides the export import container visibility service across the Western corridor of India along with comparative performance metrics. It is an end-to-end tracking system of container movement across all ports to the inland container depots, container freight stations and end users, via toll plazas and railway movement on an integrated basis.

The LDB system, currently covering 95% of Indian ports, is based on the FIWARE platform, and relies on several of its key features. According to Capt. Vinod Nair, VP Operations K-Line Shipping Line, LDB helps us to track the route and the movement of a container, which had met with an accident. This real-time tracking was of immense help to all the stakeholders.

Solution

DMICDC Logistics Data Services Ltd was incorporated on 30th December 2015 as a joint venture company between DMIC Project Implementation Trust Fund (DMIC Trust) & NEC Corporation, Japan with 50% equity from both parties. The LDB Project was conceptualized and is currently being executed with support from various Ministries and Departments of the Government of India. Today, it is one of the most promising container tracking management systems in the market.

The designed LDB system is based on real-time tracking with a magnetic radio-frequency identification (RFID) tag attached to the container. Every time it passes through a toll plaza, the container movement is recorded by the RFID reader and shared with the LDB system, until it reaches the inland container depot or container freight station.

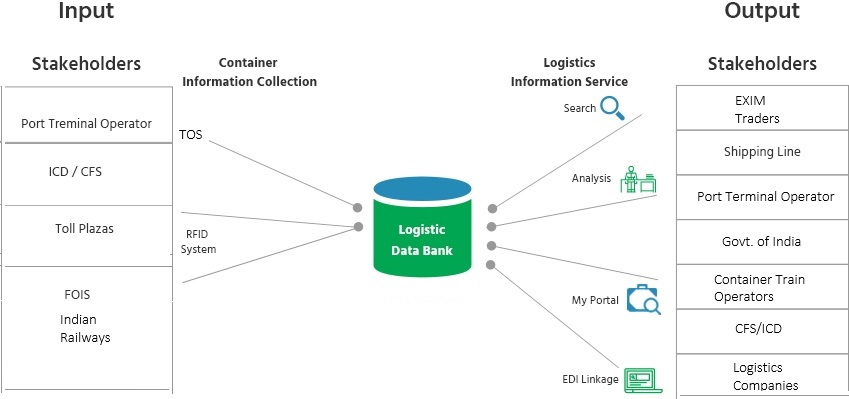

Figure 1 . Data Flow

With the FIWARE subsystem in the core of the LDB solution, the RFID/container information is captured and processed in real-time. FIWARE Open Source Technology provides open and standard interfaces and makes the solution easily scalable, secure and interoperable.

The LDB solution provides a single window interface to registered users, who can check the container status and location online by entering the container number at the LDB portal or mobile application. The LDB system provides a web-based container search function by container number, visualized on Google Maps, identifies delays and sends notifications to the user via e-mail or SMS.

LDB analytics reports are published on a monthly basis which provide insights into the stakeholders’ performance across the competitive landscape. They are shared with all stakeholders concerned with which interns help in identifying the bottlenecks effectively to ensure better planning and streamlining of the processes, reducing the lead time, which, in turn, will help in bringing down the overall transaction cost. LDB provides detailed analysis of dwell time, average delivery time, efficiency of different port operators, CFSs/ICDs and toll plazas that are helping identify bottlenecks across the supply chain.

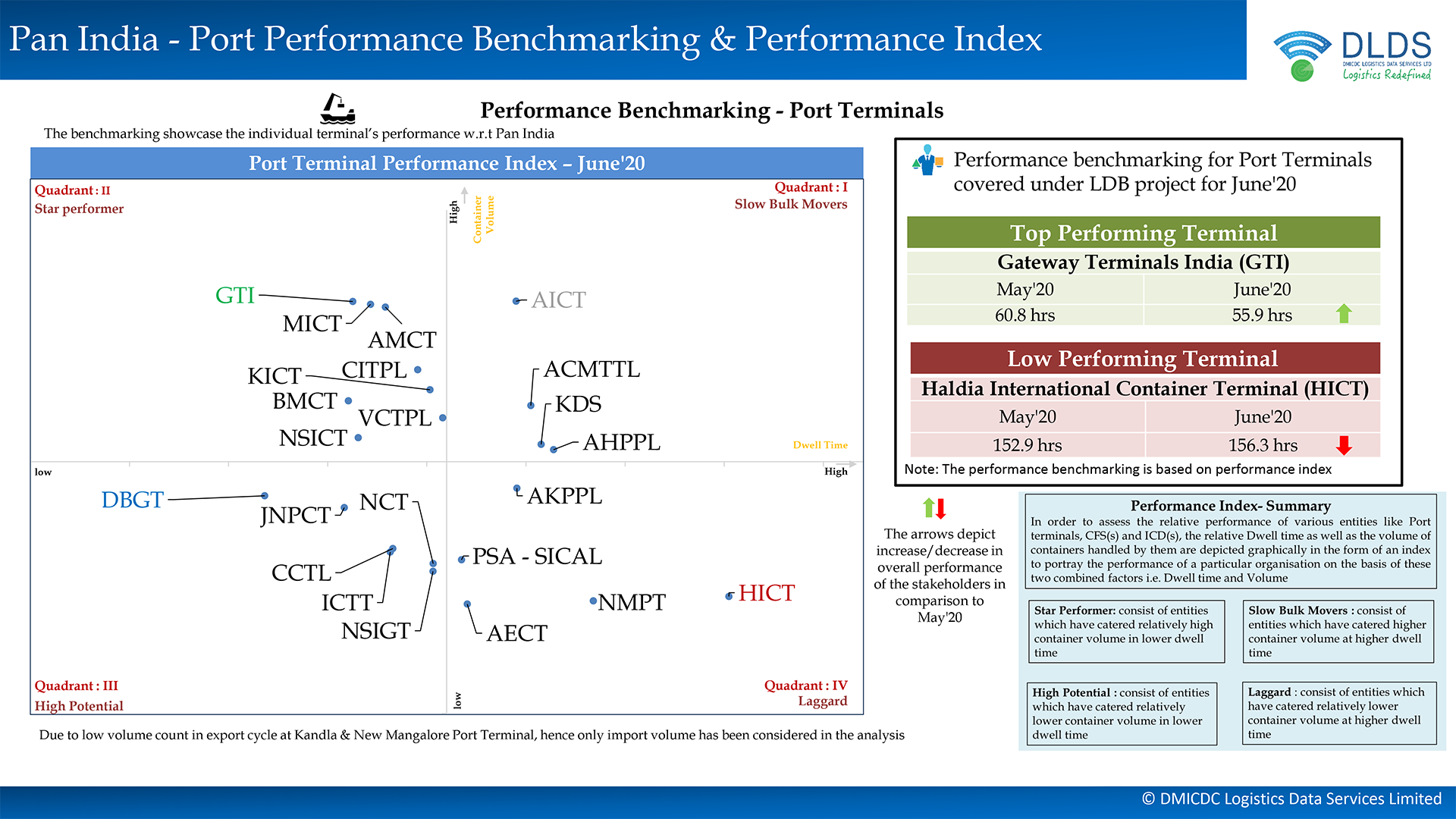

Performance Benchmarking Reports

Capturing and analyzing the dwell time of ports, CFSs and ICDs help to bring efficiency to operations, compliance across systems and better handshaking between different stakeholders.

Figure 2 . Performance Benchmarking

Congestion Analysis Reports

Capturing and analyzing the transit time helps in identifying reasons for congestion in road and rail movement and in the nearby areas of ports, ICDs and CFSs.

LDB changes simple vertical data into horizontal valuable information. The LDB solution can be summarized in the following workflow:

- Preparation — Data collection from all stakeholders;

- Basic Search — Generating container information for tracking by users;

LDB Analytics — Analyzing information (Business Intelligence) and customizing it for stakeholders, to provide a stakeholder-oriented perspective and descriptive and predictive analysis.

How it works

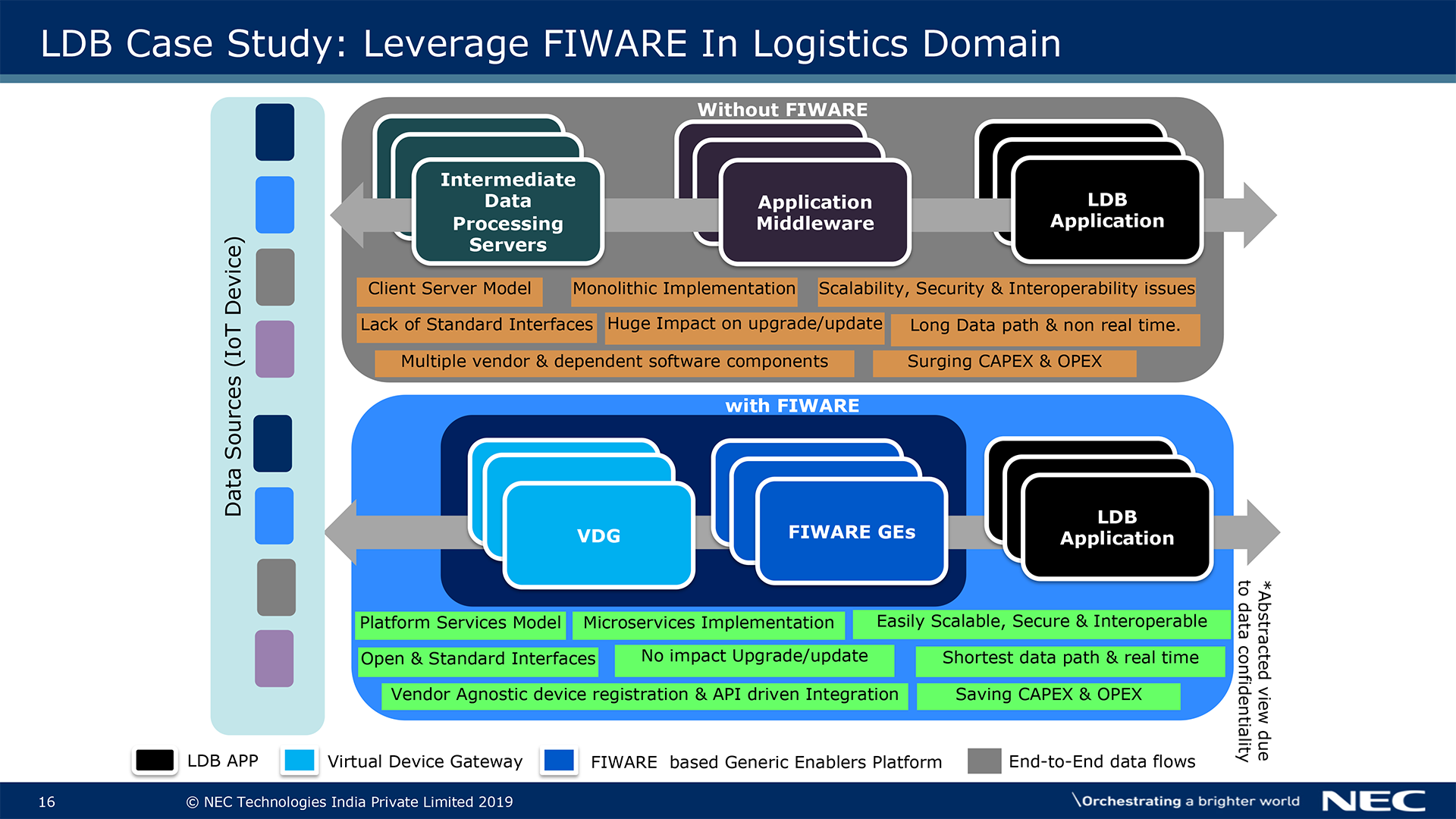

LDB-FIWARE integration is a SaaS over PaaS designed to reduce the latency in reception and processing of data.

RFID readers are located across CFS/ICD/TollPlazas to capture the movement of containers. The LDB solution comprises two units — the FIWARE sub-system and LDB sub-system. The FIWARE sub-system is interfaced with RFID devices. FIWARE components or Generic Enablers (GEs) are able to capture the JSON format data from RFID and filter the data further as per specified business rules before passing on to the LDB application to further maintain the container trails.

The high available deployment model comprises FIWARE GEs along with the new component developed by NEC Technologies India (NECTI), i.e. VDG (Virtual Device Gateway).

VDG is a service, which consists of security abstraction, data validation and a work scheduler for other components in the IoT Platform. This component improves data reliability, performance and functional interface and it can be perceived and leveraged as a digital twin in the future.

Role of FIWARE GEs in LDB solution:

- IDM provides the device authentication;

- Wilma authenticates the received Json data;

- IoT Agent validates the JSON data against the registered data model;

- Rule Engine enriches the data based on defined pre-conditions and sends the enriched data to Orion context broker;

- Draco stores the data in a historical database. This database is used by LDB applications for search and tracking of freight containers.

In the LDB solution, the FIWARE IoT Platform has been enhanced from three viewpoints:

- Feature enhancement for design improvement, data reliability, smart data visualization and functional hardening of various FIWARE GEs e.g. IoT agents, Orion, Draco, Keyrock etc;

- Security for devices has been added to offer authentication, authorization in a generic way to leverage any kind of IDM and security abstraction. It also addresses the security issues of devices that may have limited computing power and find it hard to process security logics;

- Performance improvement from 300–400 transactions per sec to 25+k transaction per second has been achieved. NECTI has achieved this using its own component VDG (Virtual Device Gateway) along with FIWARE components.

Benefits & Impact

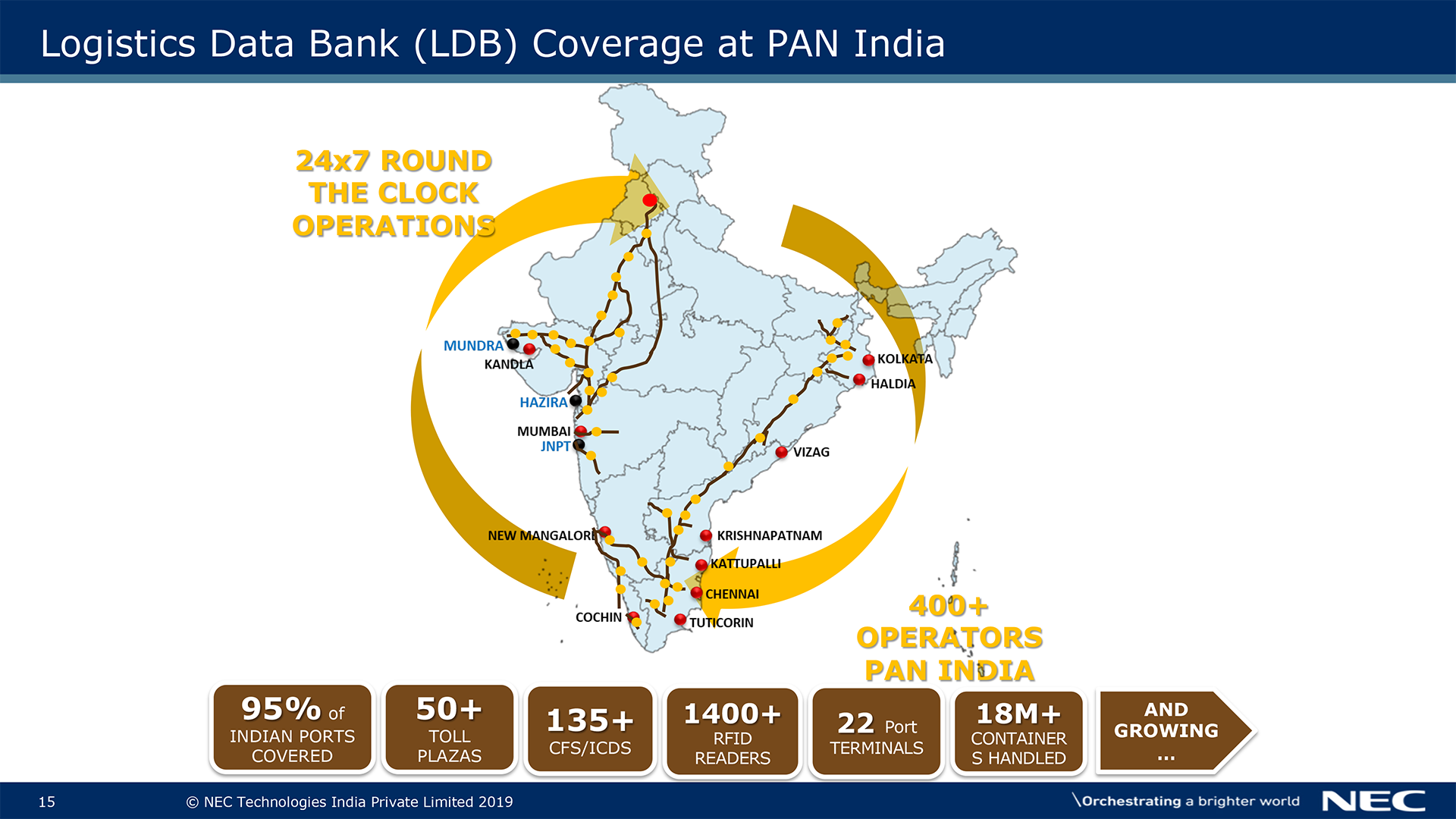

LDB Coverage

LDB is currently handling 95% per cent of India’s container volume with a milestone of 26 million+ EXIM containers tracked by its single window interface till date.

The Operations snapshot is provided below:

Figure 3 . Ports in India where LDB is adopted

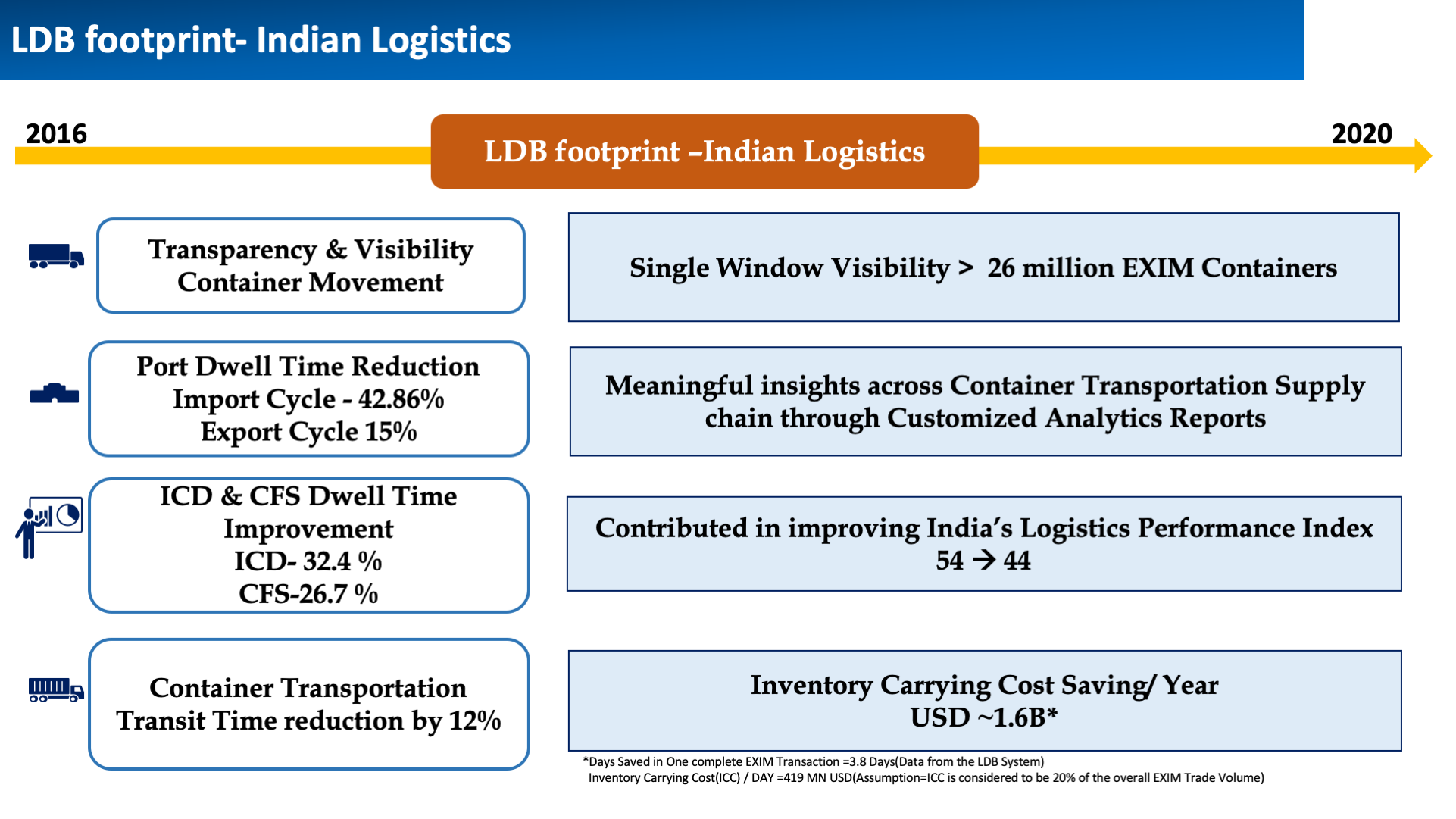

The LDB solution has benefitted the Logistics Industry in many ways:

- Improved container movement visibility;

- Improved efficiency of transshipment operations;

- Improved stock management;

- Reduced logistics costs;

- Improved accuracy of production planning;

- Reduction in Transit Time by doing congestion analysis, where the exact problem causing area is highlighted;

- Shortened logistics lead time;

- Improved Dwell Time Performance.

Figure 4 . Footprint Logistics

However, the benefits of LDB are not limited to the Logistics Industry only. It has made a huge difference to other areas like the Indian economy, environment, financial benefits for manufacturing companies and benefits for all stakeholders like Ports, CTOs and ICD/CFS.

Benefits to the Indian Government Economy

- Reduced lead time for the overall import-export cycle;

- Robust infrastructure for businesses to increase international competitiveness;

- Boosting the manufacturing sector in India, leading to more employment opportunities.

Financial benefits

Reduced inventory-carrying costs for manufacturing companies, due to a shorter and more stable lead time, as well as a shorter inventory carrying period.

Environmental Benefits

Expansion of rail transport will improve environmental conditions, as rail is better than truck transport from the perspective of environmental preservation.

Stakeholders Benefits

- Ports:

• Better workforce planning;

• Faster turnaround time;

• Transparency in delays at ports where port operations are not accurate. - CTO:

• Aid in better handshaking with other stakeholders;

• Improvement in the quality of service promoting railways as a faster and cheaper mode of transport. - ICD/CFS:

• Empty container management;

• Demand forecasting;

• Increase in containerized cargo. - NHAI (National Highway Authority of India)

• Reconciliation of toll collections;

• Analysis of chokepoints;

• Better route planning.

Added value through FIWARE

The first commercial deployment of FIWARE by NECTI was carried out successfully for DMIDC DLDS’s LDB service in the last week of September 2019 with the target to track 1+ million IoT-enabled container entities per month, using the FIWARE platform.

FIWARE, the core of the LDB solution, empowers the system by providing simple, generic, yet powerful open standards. With FIWARE NGSI Restful API, the LDB platform is now easily scalable, secure and interoperable.

The value-adds provided by FIWARE in the LDB solution are:

- Platform Services Model

The previously implemented client server model is now a SaaS over PaaS model with microservices implementation. - Shortest Data Path and real time data processing

RFID/Container information is captured and processed in real time through the FIWARE subsystem in LDB. - Better performance and capability

Currently, LDB with FIWARE can support ~6 Million transactions per hour (the LDB performance requirement was ~10K transaction per hour peak load). - Multiple IoT data format/device protocol support

With the FIWARE subsystem, LDB can now support multiple IoT data protocols like LWM2M, LoraWaN, UltraLight2.0 (UL) over HTTP /MQTT etc. - No Device vendor Lock-in

With FIWARE, LDB can now support any IoT device which works on standard IoT protocols, as mentioned above, making it easy to integrate devices from other vendors.

So, all weaknesses and limitations for mission critical properties like performance, security, data reliability, operability, availability and connectivity, can be addressed to easily uplift FIWARE as the best choice candidate for production grade IoT solutions.

By developing the new VDG component, NECTI has also made FIWARE stronger. The remarkable achieved performance throughput is now 1600 requests/second with existing component optimization and 25k per second with newly developed VDG component, delivering quality to end customers.

Figure 5 . Architecture

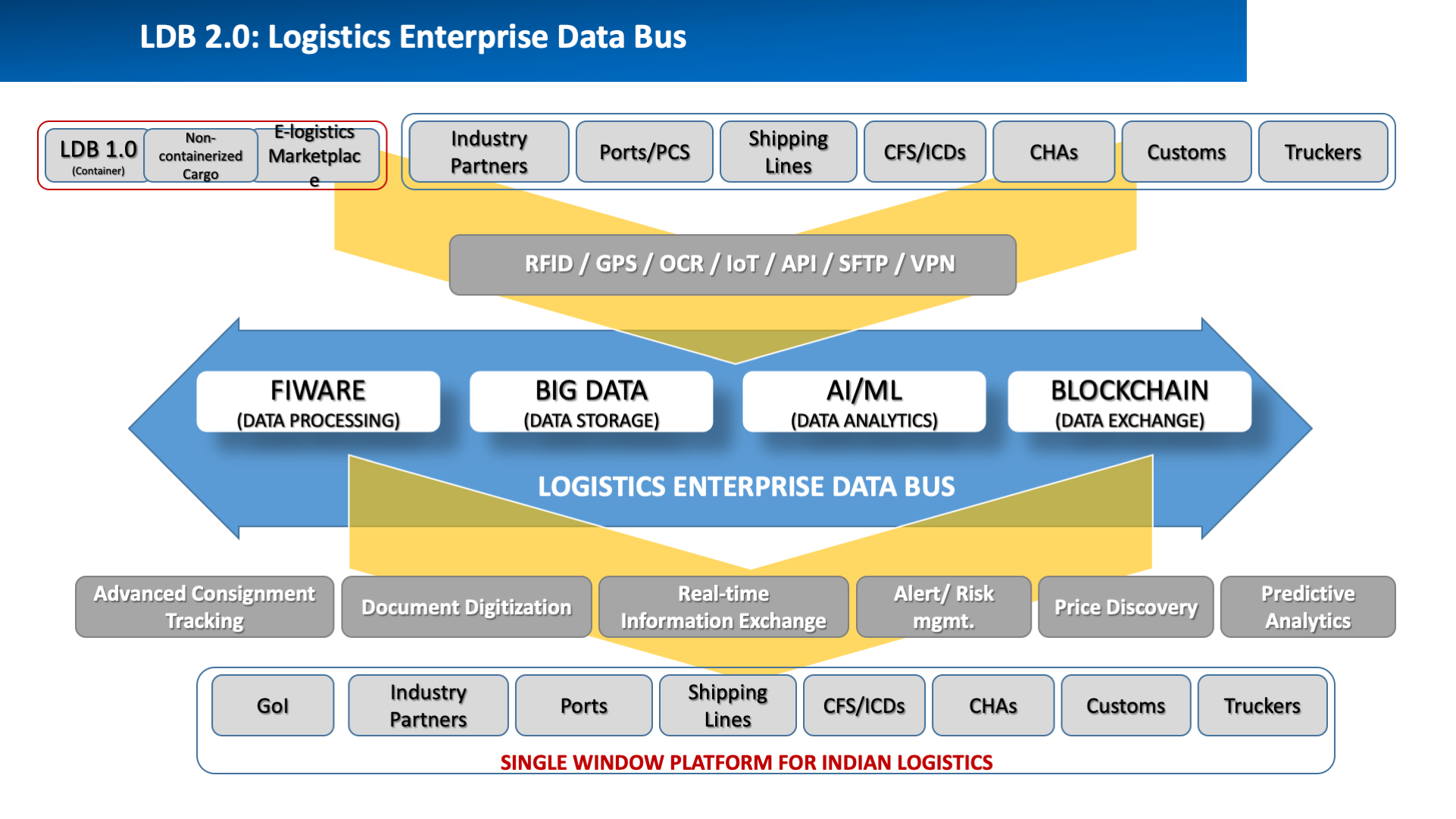

Next Steps

In the future, the focus will also include LDB’s contribution to the Logistics Performance Index (LPI). “Track and Trace” is one of the six parameters of LPI and significantly influences the “Trading across borders” parameter of Ease of Doing Business (EoDB) Index. With seamless, single-window tracking of the EXIM containers, LDB is contributing immensely to India’s improved ranking.

The expansion plan has been designed to effectively contribute to India’s Logistics Performance Index (LPI) parameters.

Figure 6 . Architecture in the future